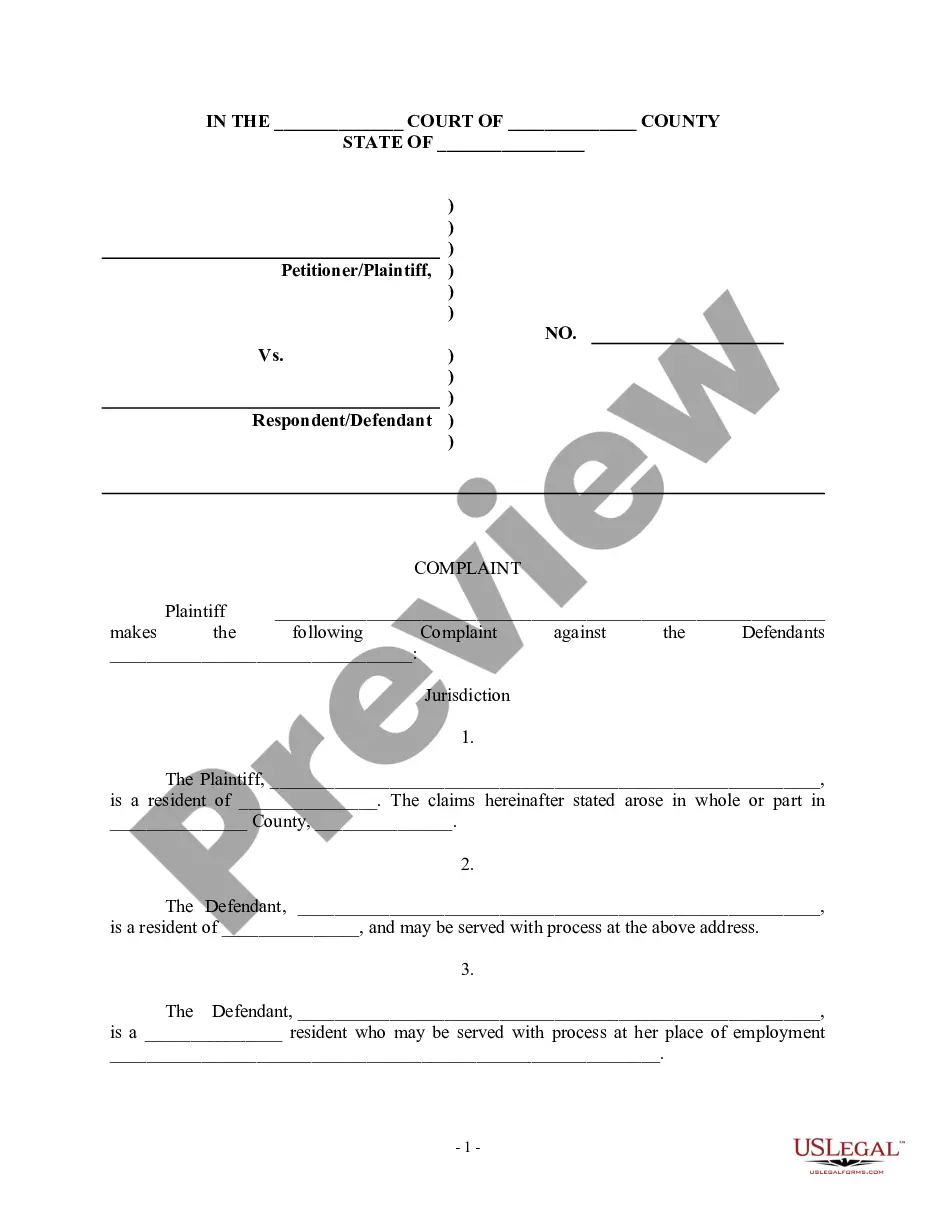

This is a multi-state form covering the subject matter of the title.

Product Defect Examples In Travis

Description

Form popularity

FAQ

In Six Sigma, a defect is a failure of a product or process. Defects are a major part of the Six Sigma program because they point to a problem that needs to be solved.

Manufacturing Defects For example, a screw might not be tightened properly during assembly, causing it to come loose during the operation of the product. Other examples include poor quality control standards or lack of testing before the release of a product onto the market.

There are three types of product defects: design defects, manufacturing defects, and warning/instruction defects. All three types of defects have to do with a product being faulty or inadequate in some way.

Six Sigma is a statistical term used to measure the number of defects that processes create. The term implies high-quality performance because a process performing at a Six Sigma level allows only 3.4 defects per one million opportunities.

A product defect is any characteristic of a product which hinders its usability for the purpose for which it was designed and manufactured. Product defects arise most prominently in legal contexts regarding product safety, where the term is applied to "anything that renders the product not reasonably safe".

A toy box was defectively manufactured – the hinges were not installed properly on the lid. If a child is playing with the box and the lid closes too quickly because of the defective hinges, it can cause serious injuries to the child.

Six Sigma is a set of methodologies and tools used to improve business processes by reducing defects and errors, minimizing variation, and increasing quality and efficiency. The goal of Six Sigma is to achieve a level of quality that is nearly perfect, with only 3.4 defects per million opportunities.

Defining Defects A defect is a failure to fulfill customer quality expectations in most cases. It is tempting to think that business leaders can determine what quality means for a particular product or process. However, Six Sigma's central principle is that quality is defined by the customer.

A toy box was defectively manufactured – the hinges were not installed properly on the lid. If a child is playing with the box and the lid closes too quickly because of the defective hinges, it can cause serious injuries to the child.

To successfully sue for a defective product, you need to prove that: The defendant designed, manufactured, distributed or sold a defective product to the consumer. The consumer used reasonable care when using the product. The consumer was injured due to the defect in the product.