Lead Paint For X Ray Room

Description

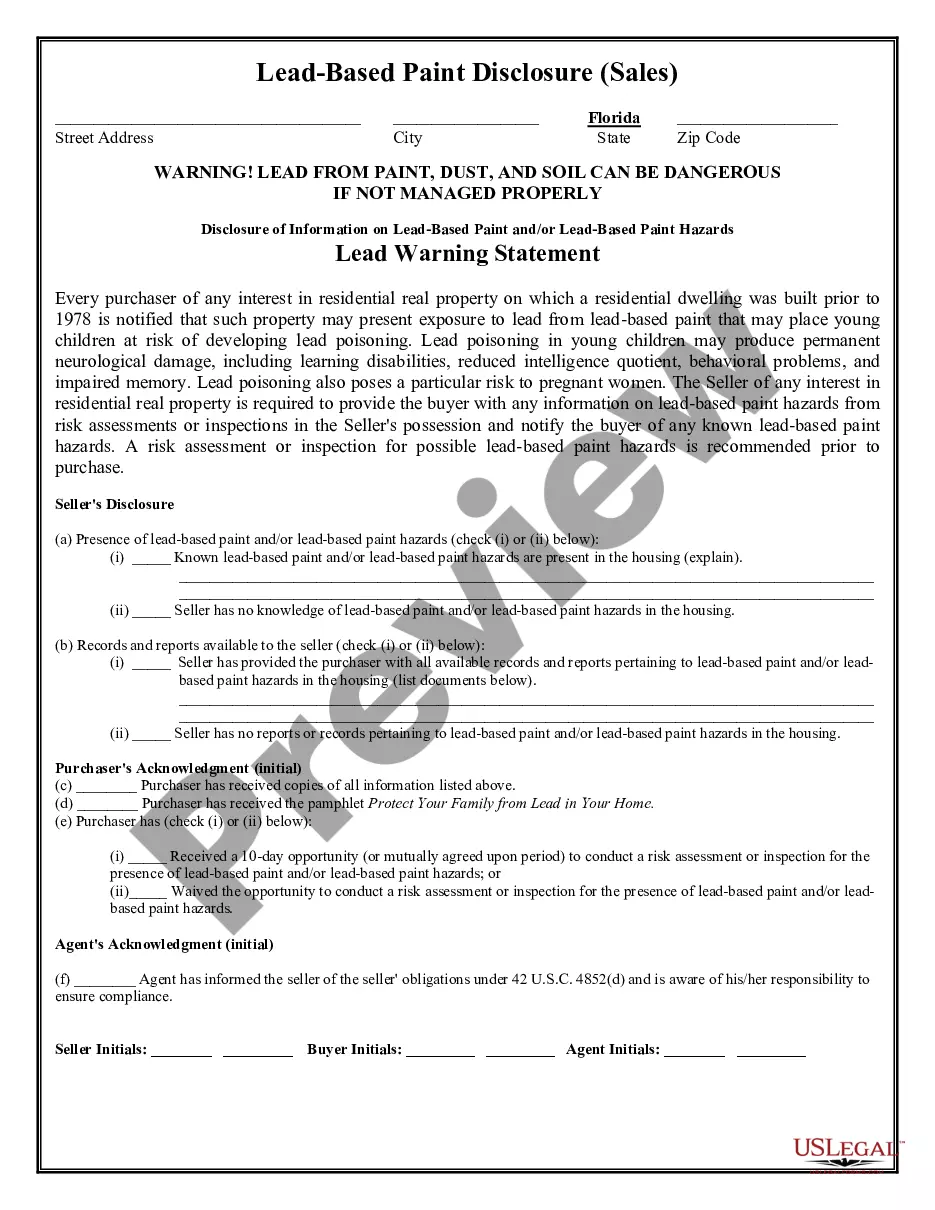

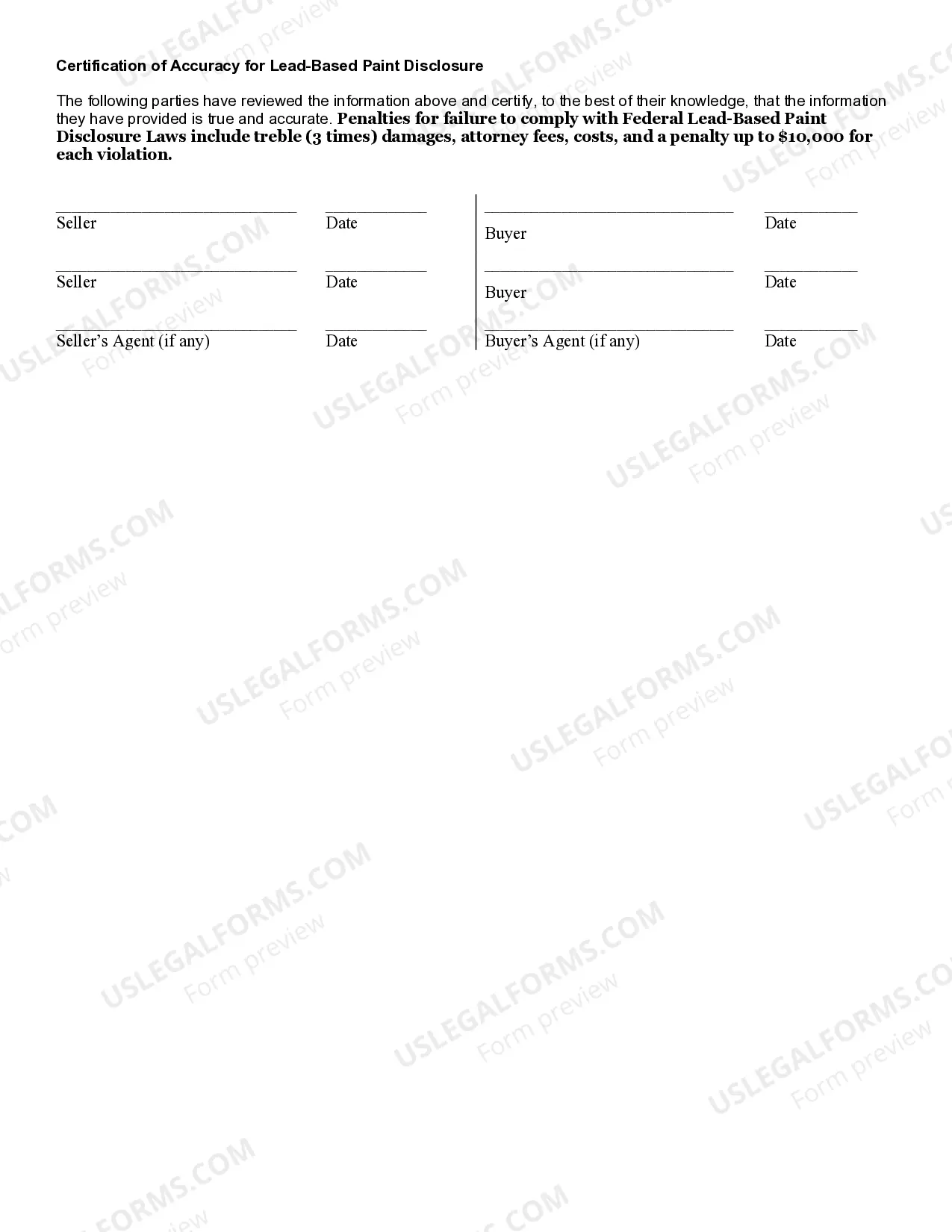

How to fill out Florida Lead Based Paint Disclosure For Sales Transaction?

Legal documents management can be perplexing, even for the most experienced professionals.

When you are searching for a Lead Paint For X Ray Room and cannot find the time to look for the correct and updated version, the process may be challenging.

- Access state- or county-specific legal and commercial documents.

- US Legal Forms addresses all your needs, from individual to business paperwork, all in one location.

- Utilize cutting-edge tools to complete and manage your Lead Paint For X Ray Room.

Form popularity

FAQ

Lead-lined wall panelling increases the density between the partition and external walls to protect the exterior of the radiography room from the radiation contained within it. Lead thicknesses range from 1mm to 3.5mm for each board, but higher lead equivalences can be achieved by installing multiple layers.

Any sanding, scraping, chipping, or other forms of friction against a lead paint surface can release particles of lead dust into the air. Instead, simply wipe down the existing surface with a warm, wet towel to prepare it to be painted over.

Lead Lining Explained This helps keep everyone safe from potential exposure to harmful levels of radiation. It also helps keep the x-ray machine in working order since it won't have to work as hard to produce enough energy for its purpose.

1 Should the change cubicles lead into the x-ray room the doors must be lined with at least 1.5 mm leadsheet. 1.6. 2 Access doors into the x-ray room must be lockable from the x-ray room side to prevent entrance during radiation exposures.

There must be lead between the walls (interior and exterior) and other rooms of an x-ray room as lead-lining protects patients from radiation exposure by shielding the patient from both x-rays and gamma rays.