Hold Point Inspeção

Description

How to fill out Arkansas Buyer's Home Inspection Checklist?

- If you are an existing user, log in to your US Legal Forms account and access the form you need by clicking the Download button. Ensure that your subscription is active; if not, renew it as needed.

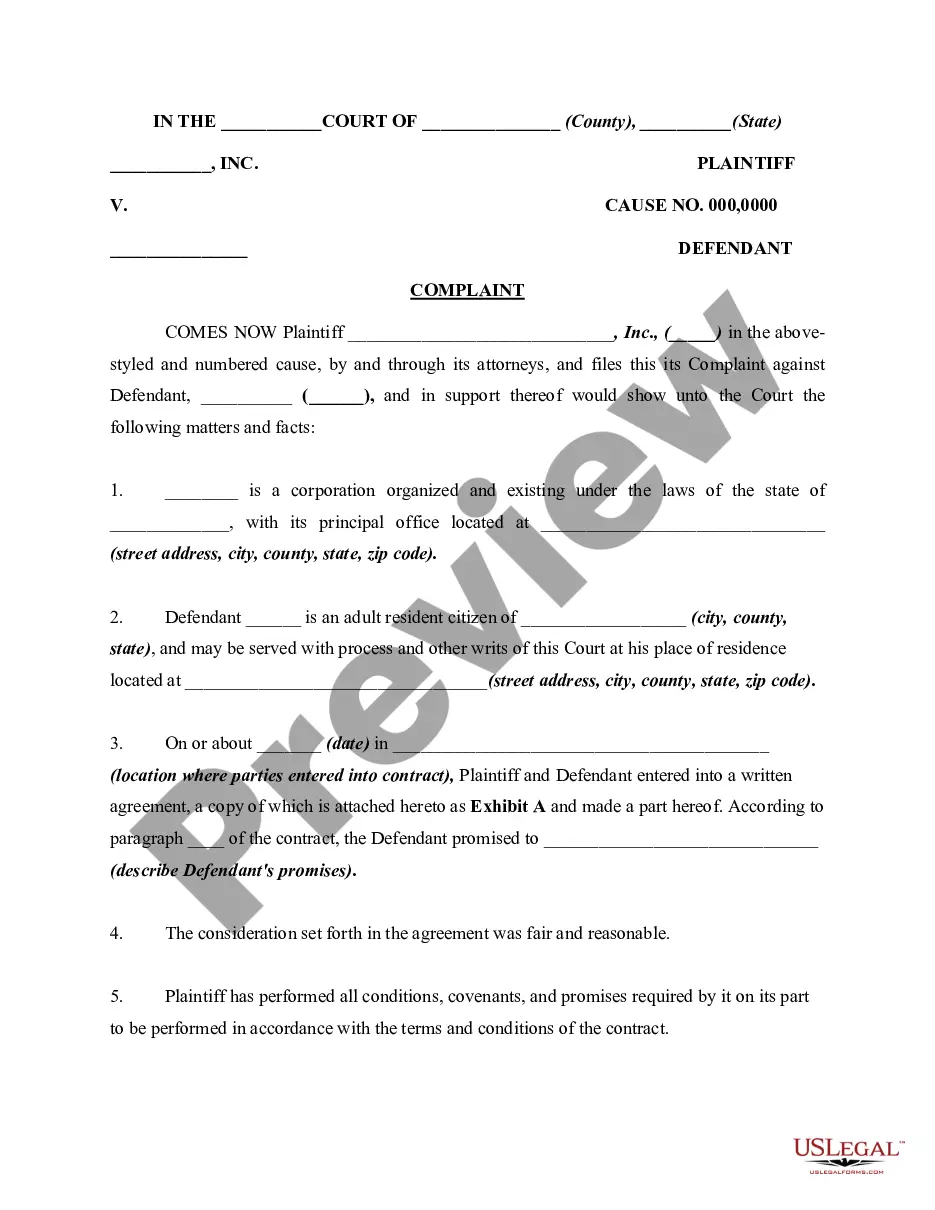

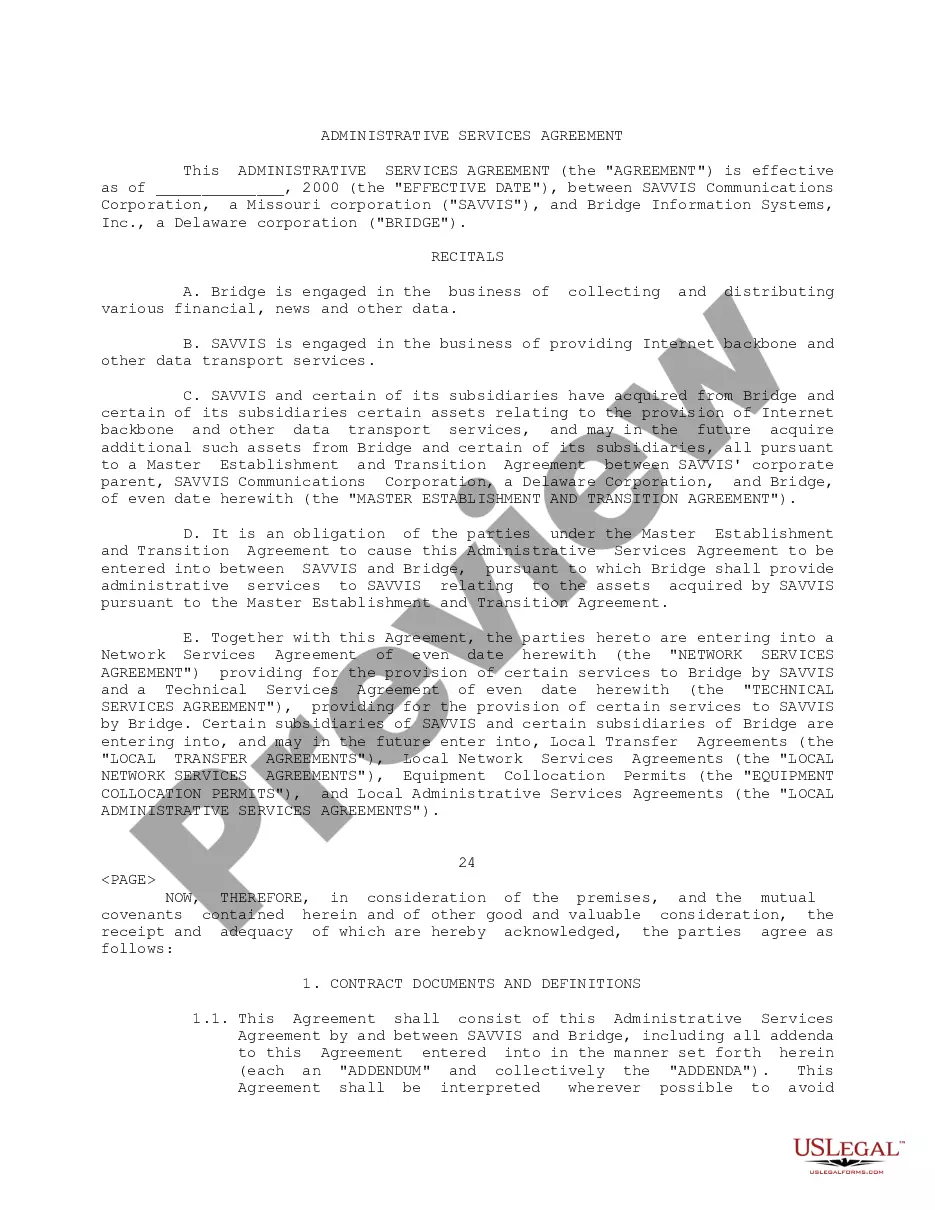

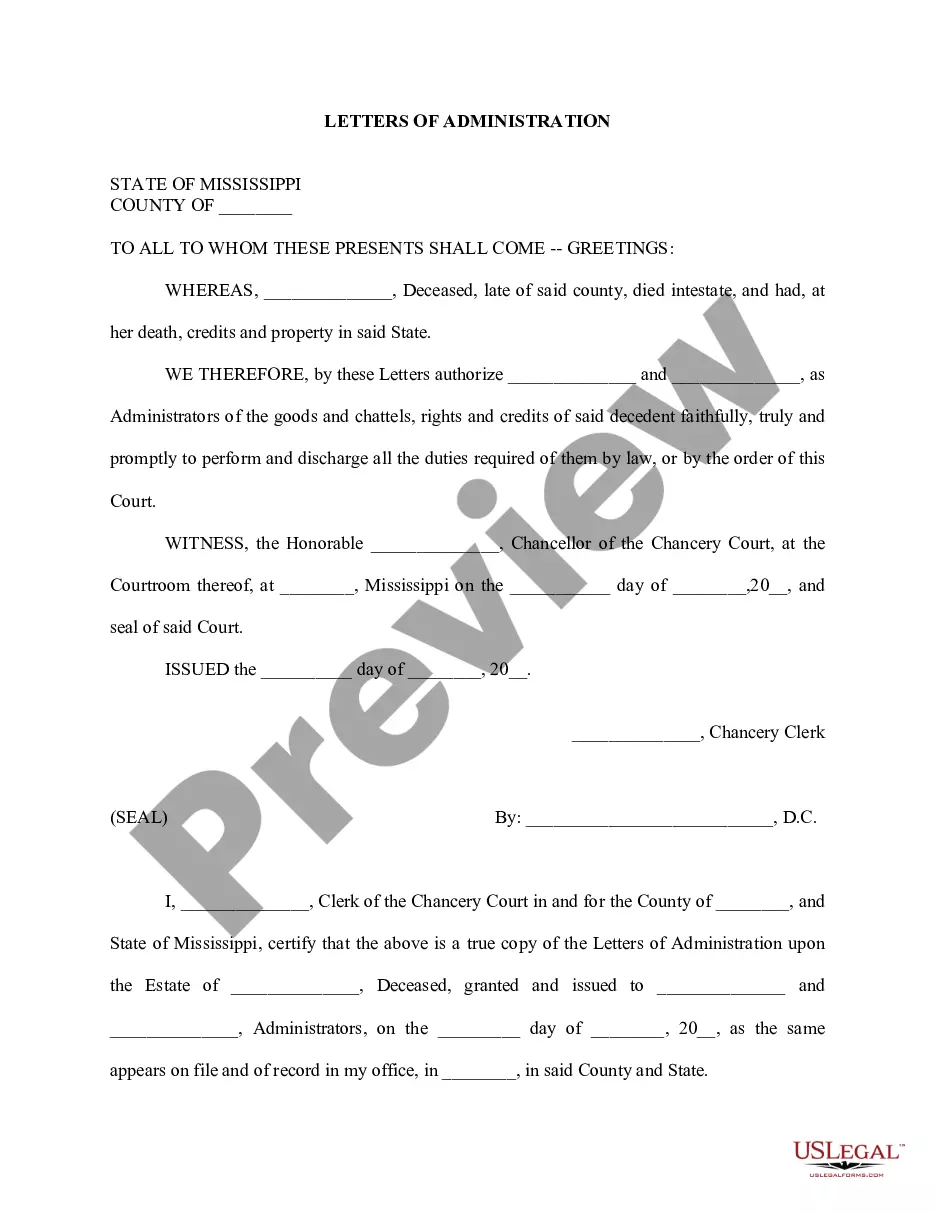

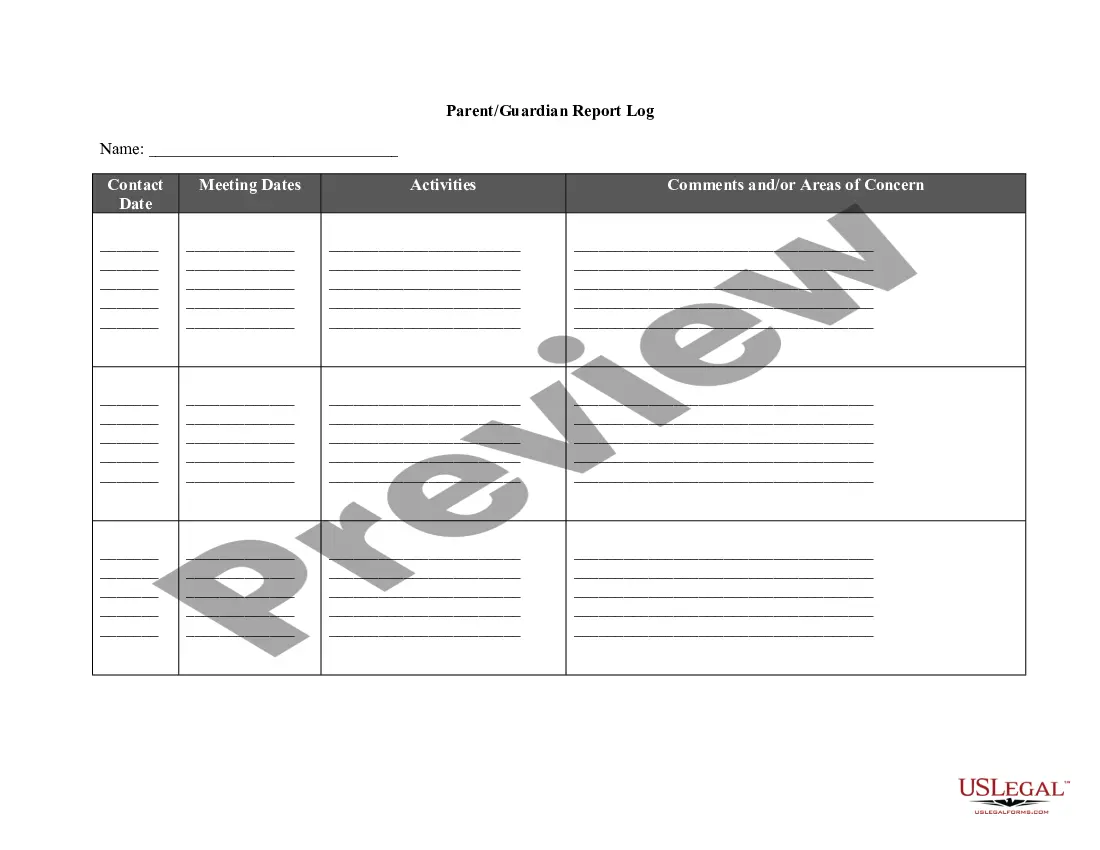

- For first-time users, start by browsing through the Preview mode and the form descriptions to ensure you select the appropriate document that complies with your local requirements.

- If you find the initial form unsuitable, you can always utilize the Search feature at the top of the page to discover the correct template.

- Once you've identified the right document, proceed to purchase it by clicking the Buy Now button and selecting your desired subscription plan. Create an account to unlock full access to the library.

- Complete your purchase by entering your payment information, either through credit card or PayPal.

- Finally, download the form to your device. You can revisit it at any time from the My Forms section in your account.

With over 85,000 easily fillable and editable forms, US Legal Forms stands out for its extensive online library. You can even consult premium experts to assist you in completing your legal documents accurately.

Ready to simplify your legal document needs? Visit US Legal Forms today and discover how easy it is to access the forms you require.

Form popularity

FAQ

A hold point is a specific juncture in a process where further action is paused until approval or verification is received. This pause allows for assessments to confirm compliance with regulations or standards. Understanding the concept of hold point inspeção is essential for maintaining quality and efficiency in operations. It serves as a safeguard to ensure all elements are satisfactory before proceeding.

A hold inspection is a critical evaluation phase in various processes, typically occurring before moving forward. It ensures that everything meets specified standards and requirements before approval. This step minimizes risks and ensures quality control, making it especially relevant to hold point inspeção. Organizations benefit from implementing a structured hold inspection process.

Customer hold point refers to a designated stage in a workflow where a decision or action is pending from the customer. This ensures that the project does not proceed until the client provides necessary input or approval. Recognizing this hold point inspeção helps streamline communication and fosters trust between parties. It ultimately enhances the customer experience.

A hold in government often refers to a temporary suspension of action on legislation or nominations. For instance, a senator may place a hold on a bill to raise concerns about its implications. This action creates a pause, allowing for further review or discussion. Understanding hold point inspeção is crucial for navigating these government processes.

A 7 point inspection is a structured methodology designed to thoroughly assess the essential aspects of a project or product. This approach helps organizations ensure that all necessary standards and regulations are met, promoting safety and efficiency. Utilizing a hold point inspeção as part of the 7 point process allows teams to catch issues early, preventing delays and reinforcing quality assurance. By adopting this method, you invest in the success of your project.

A hold point inspection is a crucial step in project management that requires work to halt until specific quality checks are completed. This type of inspection ensures that key standards are met before moving forward with the next phase of a project. By integrating a hold point inspeção, companies reduce the risk of costly errors and enhance project reliability. It's a strategic practice that helps maintain high standards from start to finish.

The 7 point inspection process is a comprehensive evaluation used in various industries to ensure the quality and safety of products or services. It involves checking critical points of a project, including compliance, performance, and safety measures. By implementing a thorough hold point inspeção, businesses can identify potential issues early on and make necessary adjustments. This proactive approach ultimately leads to better outcomes and customer satisfaction.

The hold point for inspection refers to specific stages in a project where work must pause for inspection to take place. It is a critical quality control measure that ensures compliance before moving forward. Adopting a thorough approach to hold points for inspection guarantees safety and quality in your project's execution.

The hold point witness point review is an evaluation that combines both hold and witness points for effective project oversight. It ensures that all required inspections are completed before any work progresses while also allowing for observational checks. This approach improves project reliability and enhances quality assurance throughout the process.

An example of a hold point may involve the verification of concrete curing before proceeding with the next phase of construction. At this stage, inspectors would check for the right conditions and compliance with specifications before allowing work to continue. By implementing hold points like this, you ensure that essential checks are performed to uphold quality.