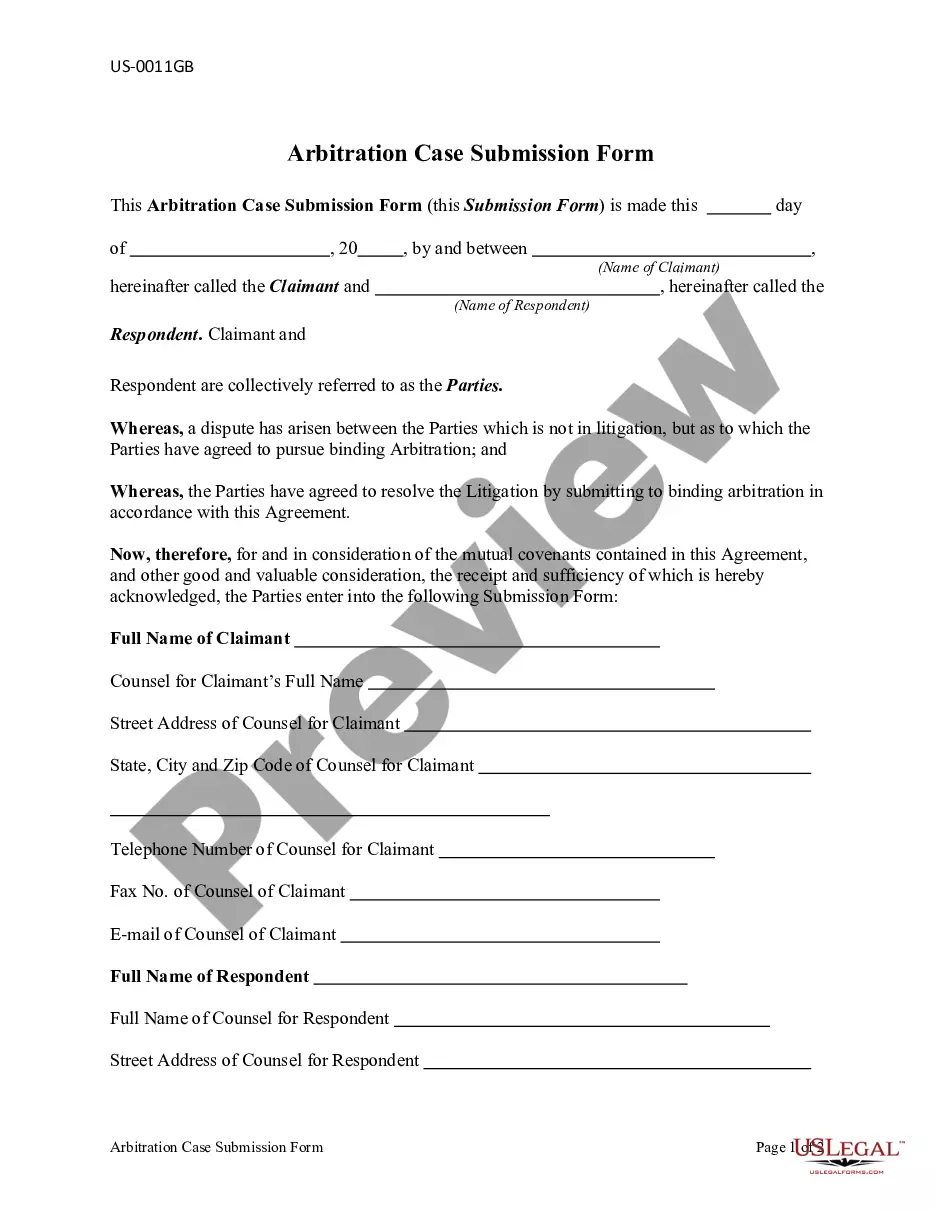

The Plugging of Wells form, the assignee shall plug all wells not capable or no longer capable of producing oil or gas in paying quantities and shall restore the lands around any such well in a manner that meets all requirements of any governmental agency having jurisdiction and the oil and gas lease on which the well is located.

Michigan Plugging of Wells

Description

How to fill out Plugging Of Wells?

Finding the right lawful file template might be a have a problem. Naturally, there are tons of themes available on the net, but how would you get the lawful type you want? Use the US Legal Forms web site. The assistance provides a huge number of themes, for example the Michigan Plugging of Wells, which you can use for business and personal requires. All the types are examined by specialists and meet federal and state requirements.

In case you are currently listed, log in for your bank account and click on the Download switch to get the Michigan Plugging of Wells. Use your bank account to search through the lawful types you may have purchased earlier. Go to the My Forms tab of your respective bank account and obtain another backup of your file you want.

In case you are a fresh end user of US Legal Forms, here are simple recommendations that you can stick to:

- First, make sure you have chosen the correct type to your town/area. You may look over the form making use of the Preview switch and read the form explanation to ensure this is basically the right one for you.

- In case the type is not going to meet your needs, make use of the Seach discipline to obtain the proper type.

- When you are certain the form is acceptable, click on the Get now switch to get the type.

- Opt for the prices program you would like and enter in the essential info. Make your bank account and purchase your order with your PayPal bank account or credit card.

- Pick the document formatting and down load the lawful file template for your gadget.

- Complete, modify and print and sign the attained Michigan Plugging of Wells.

US Legal Forms is definitely the biggest catalogue of lawful types where you will find numerous file themes. Use the company to down load expertly-produced paperwork that stick to status requirements.

Form popularity

FAQ

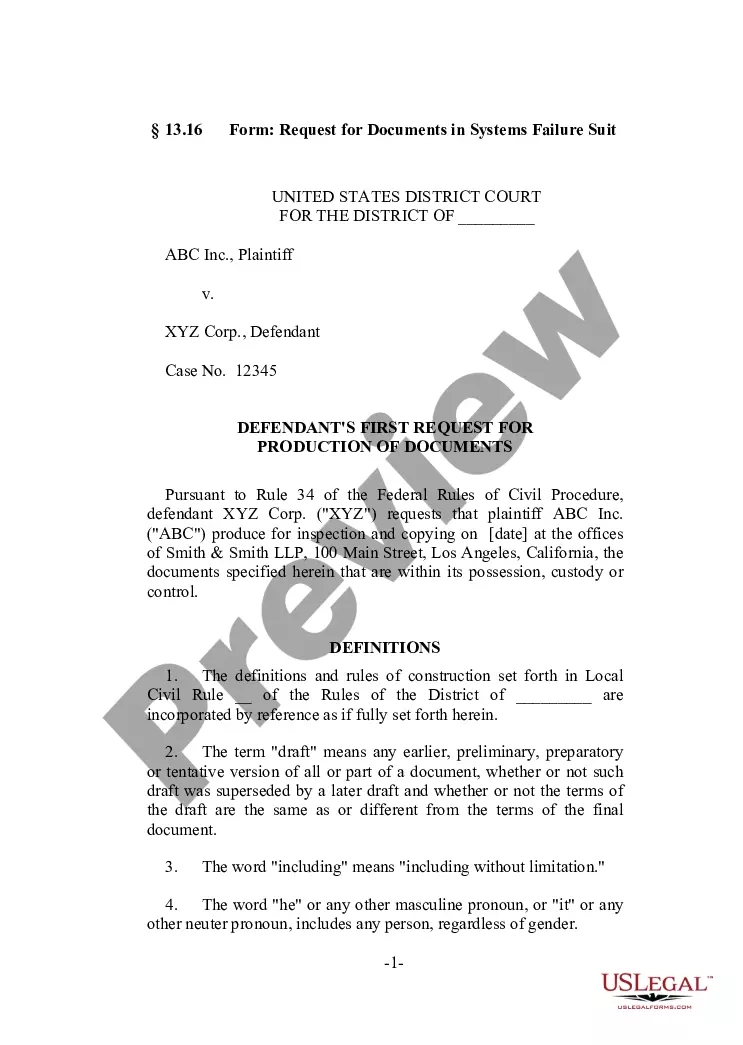

Well-plugging steps Measure the dimensions of the well. ... Remove all obstructing materials from the well. ... Disinfect the well by adding household bleach. ... Fill the well with plugging materials. ... Remove the upper 3 feet of the well casing. ... Fill the final 3 feet with topsoil and mound.

All the debris and material need to be removed for successful plugging. Once the well is cleaned out, the plugging process begins by placing cement in the well through the gas and oil-producing zones. These cement plugs, at times, are spaced within the well using bentonite gel spacers (mixtures of clay and water).

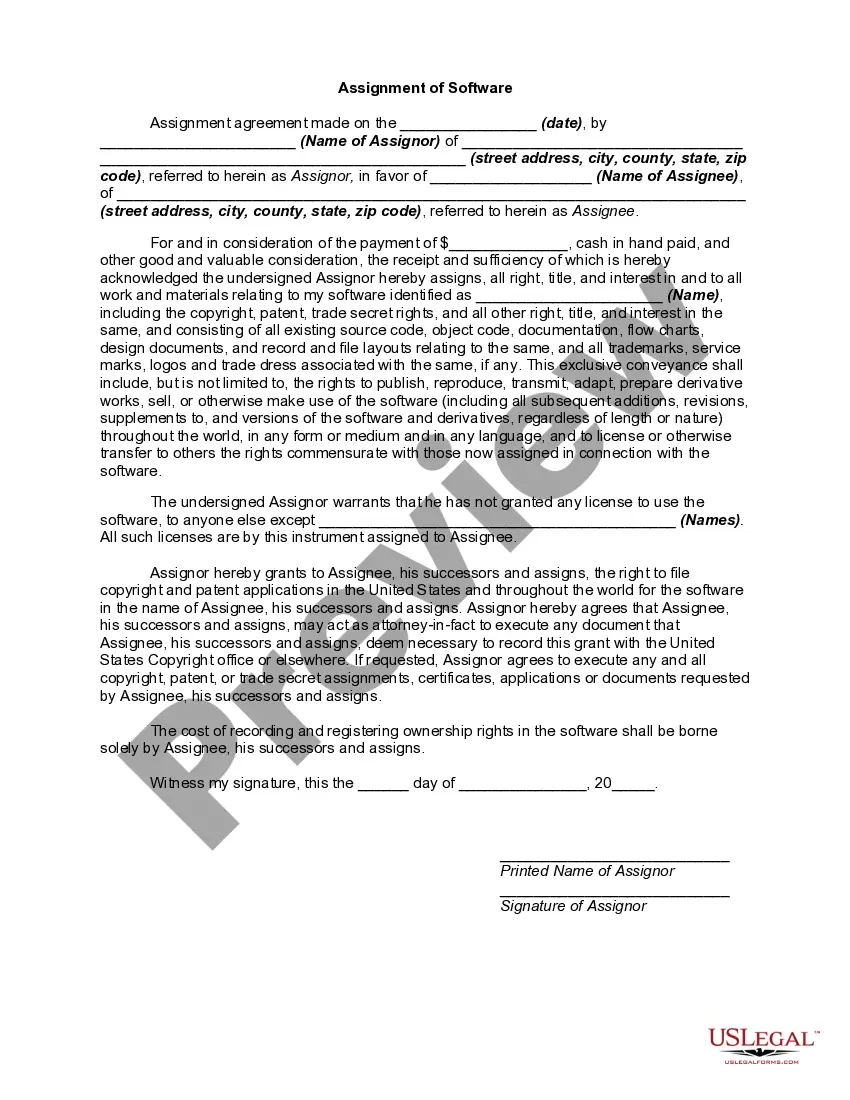

Wells drilled into completely consolidated bedrock have no need for a well screen. Typically, well depths in Michigan range from 30 to 500 feet, but most residential wells are less than 200 feet deep. Confined aquifers and unconfined aquifers respond differently to wells.

Does the home have a drilled well, and if so, when was it drilled? The average lifespan for a well is 30?50 years.

The minimum depth allowable in Michigan for a drinking water well is 25 feet. All wells must terminate a minimum of 12 inches above grade and cannot be located in a below grade pit.

How much does a new well cost? New wells generally range from $4000 to $8000. The depth of the well and static water level are big factors. A deeper well with lower static water level may require a larger pump, motor and tank to lift the water and have appropriate storage.

Who can or repair a well or pump? Only a registered well driller or property owner can drill a well. Regardless of who installs the water system, it must comply with all applicable codes. The Michigan Department of Environmental Quality registers water well drilling contractors and pump installers.

The state well code requires ?A well that is abandoned when municipal water is installed shall be plugged.? In addition, some county, local, and municipal jurisdictions have ordinances that prohibit the retention of private wells when structures are connected to municipal water service.