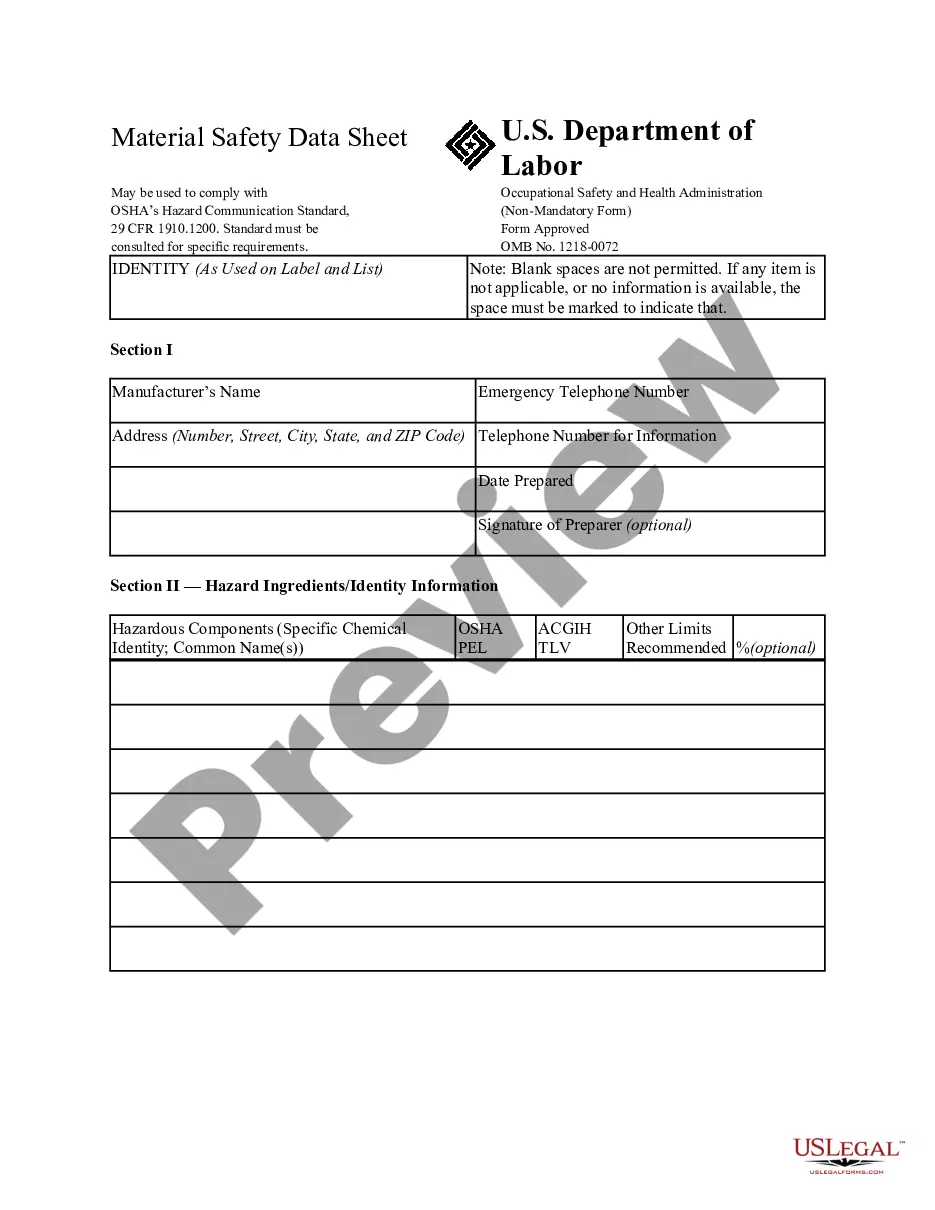

Guam Material Safety Data Sheet from the U.S. Dept. of Labor and OSHA

Description

How to fill out Material Safety Data Sheet From The U.S. Dept. Of Labor And OSHA?

Finding the appropriate legal document format can be challenging.

Certainly, there are numerous templates available online, but how will you obtain the legal form you need.

Utilize the US Legal Forms platform. This service provides thousands of templates, such as the Guam Material Safety Data Sheet from the U.S. Department of Labor and OSHA, suitable for both business and personal purposes.

You can review the form using the Review button and read the form description to confirm it is the right one for you.

- All documents are reviewed by experts and meet federal and state requirements.

- If you are currently registered, Log In to your account and click the Acquire button to get the Guam Material Safety Data Sheet from the U.S. Department of Labor and OSHA.

- Use your account to browse the legal forms you may have previously obtained.

- Visit the My documents section of your account and retrieve another copy of the document you need.

- If you are a new user of US Legal Forms, here are simple instructions to follow.

- First, ensure you have selected the correct form for your city/state.

Form popularity

FAQ

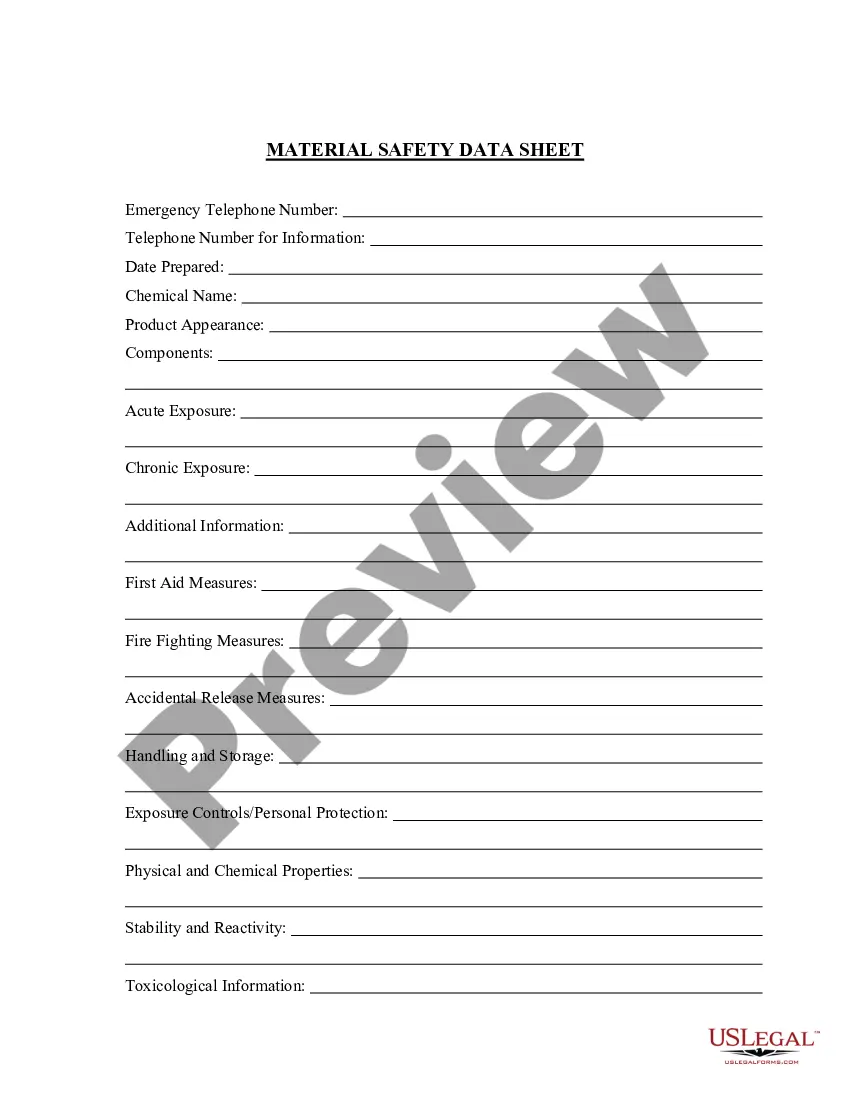

MSDSs must be developed for hazardous chemicals used in the workplace, and must list the hazardous chemicals that are found in a product in quantities of 1% or greater, or 0.1% or greater if the chemical is a carcinogen. The MSDS does not have to list the amount that the hazardous chemical occurs in the product.

Requirementsthe name of the chemical (same as on the label)the chemical and common names of the substance.a listing of the ingredients.a statement of the ingredients that are known carcinogens or that present other known hazards.any specific hazards.

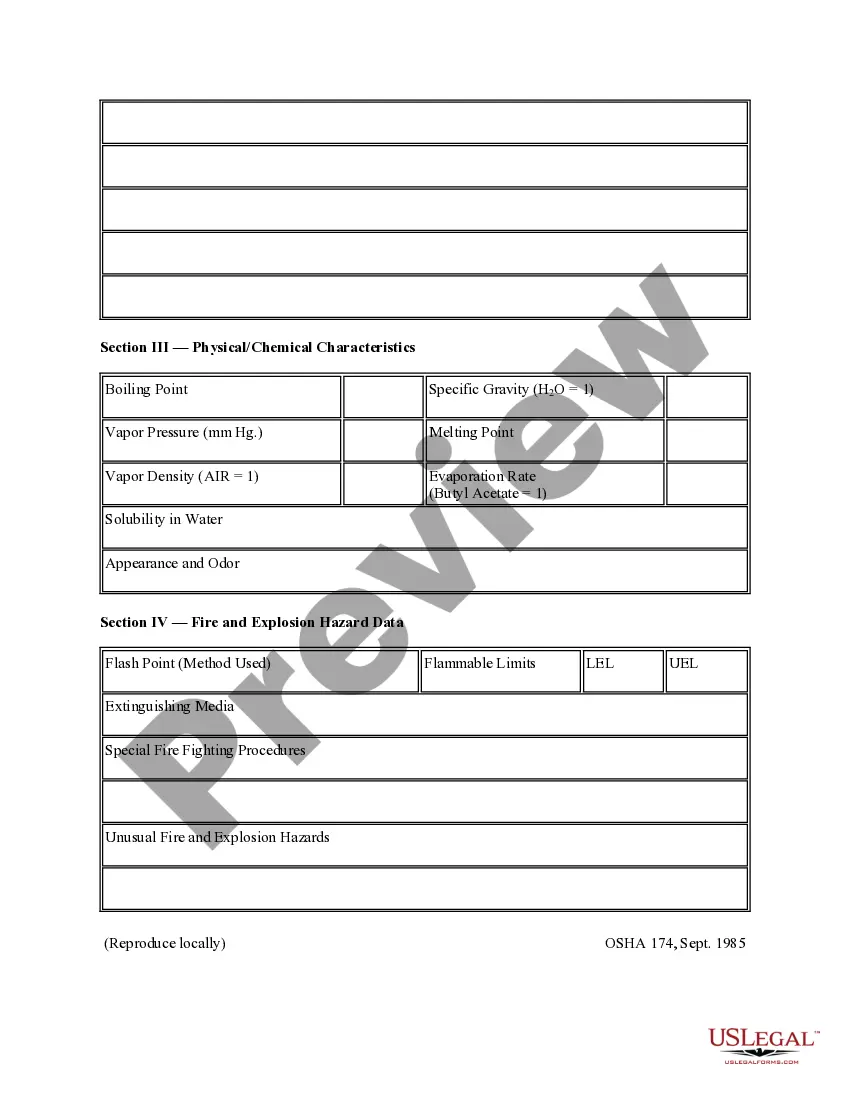

What information is on the MSDS?Product Information: product identifier (name), manufacturer and suppliers names, addresses, and emergency phone numbers.Hazardous Ingredients.Physical Data.Fire or Explosion Hazard Data.More items...

What information is on the MSDS?Product Information: product identifier (name), manufacturer and suppliers names, addresses, and emergency phone numbers.Hazardous Ingredients.Physical Data.Fire or Explosion Hazard Data.More items...

According to the ANSI standard and GHS, an MSDS should always have 16 sections, each with a fixed heading name. In addition, the sections should always follow the same order. The purpose of this standardized format it to make it easier for specific groups of people to find the information they need.

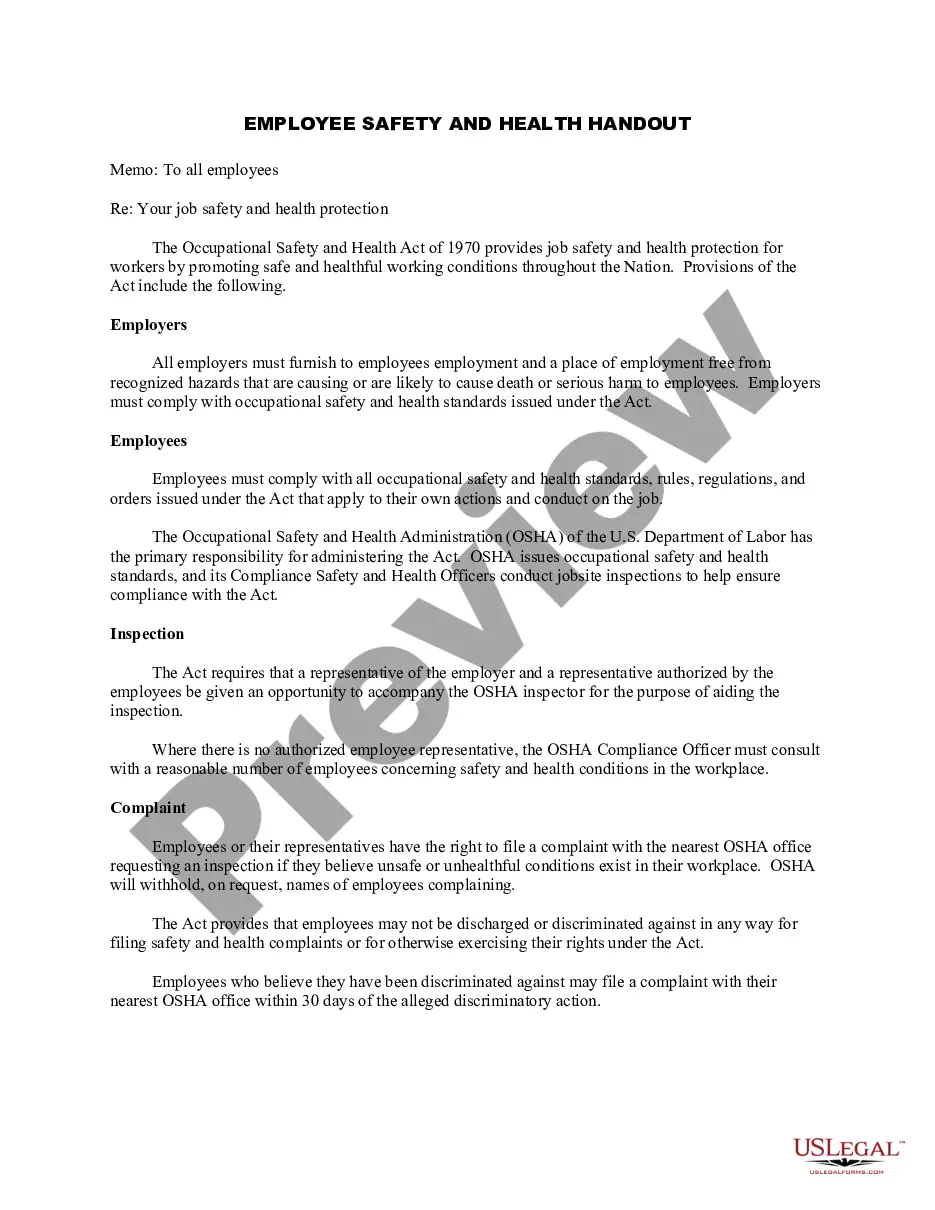

The Hazard Communication Standard (HCS) (29 CFR 1910.1200(g)), revised in 2012, requires that the chemical manufacturer, distributor, or importer provide Safety Data Sheets (SDSs) (formerly MSDSs or Material Safety Data Sheets) for each hazardous chemical to downstream users to communicate information on these hazards.

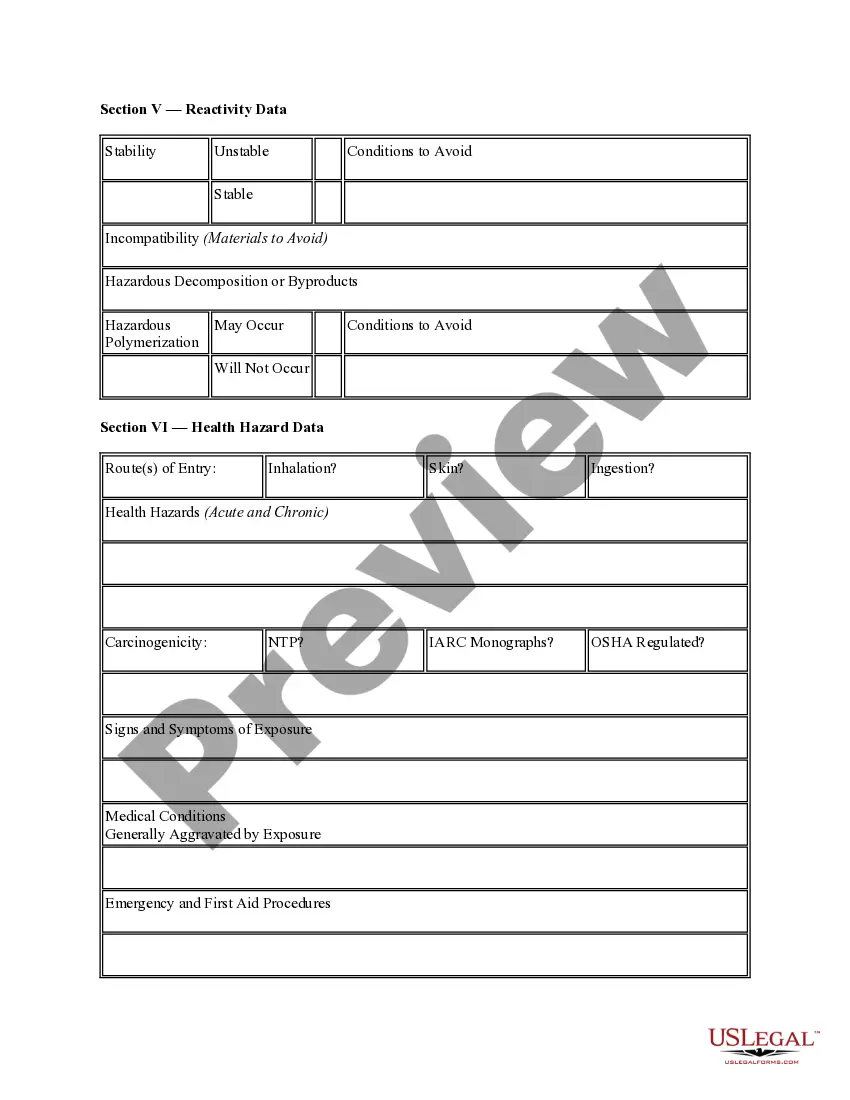

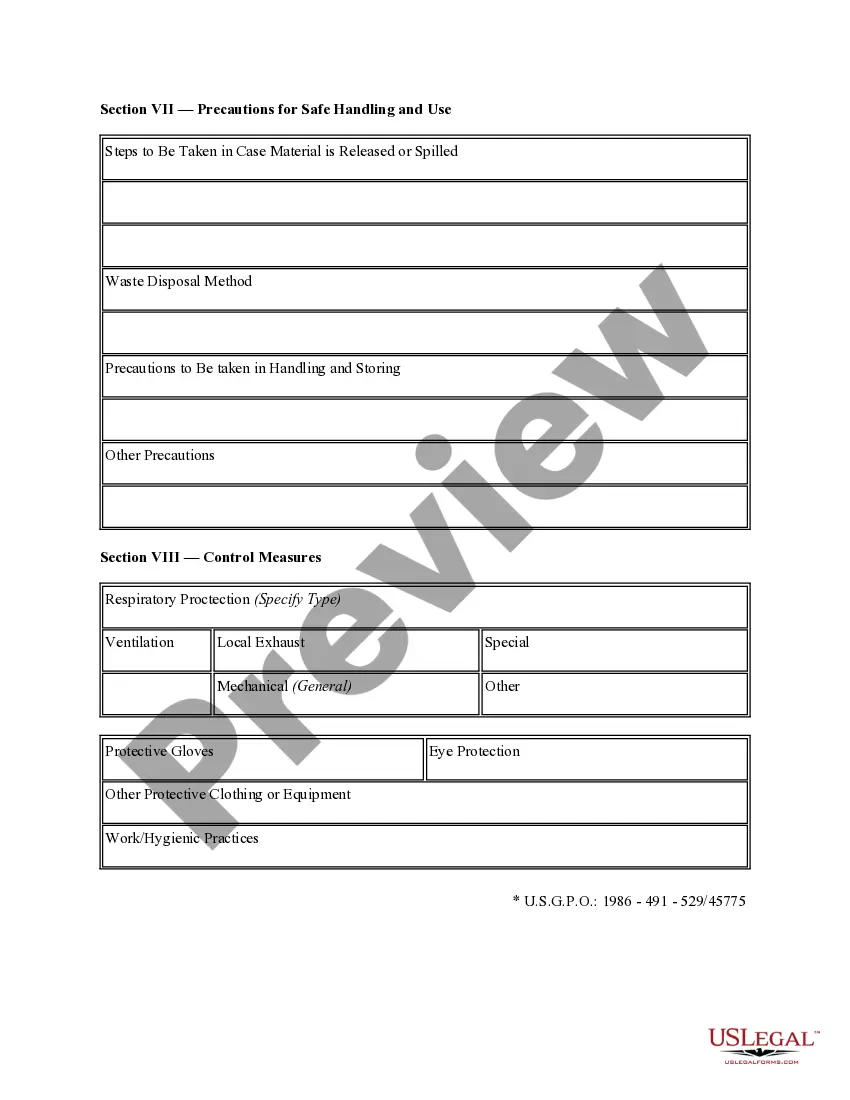

An SDS (formerly known as MSDS) includes information such as the properties of each chemical; the physical, health, and environmental health hazards; protective measures; and safety precautions for handling, storing, and transporting the chemical.

Section 4, First-aid measures includes important symp- toms/effects, acute, delayed; required treatment. Section 5, Fire-fighting measures lists suitable extinguishing techniques, equipment; chemical hazards from fire.

The MSDS lists the hazardous ingredients of a product, its physical and chemical characteristics (e.g. flammability, explosive properties), its effect on human health, the chemicals with which it can adversely react, handling precautions, the types of measures that can be used to control exposure, emergency and first