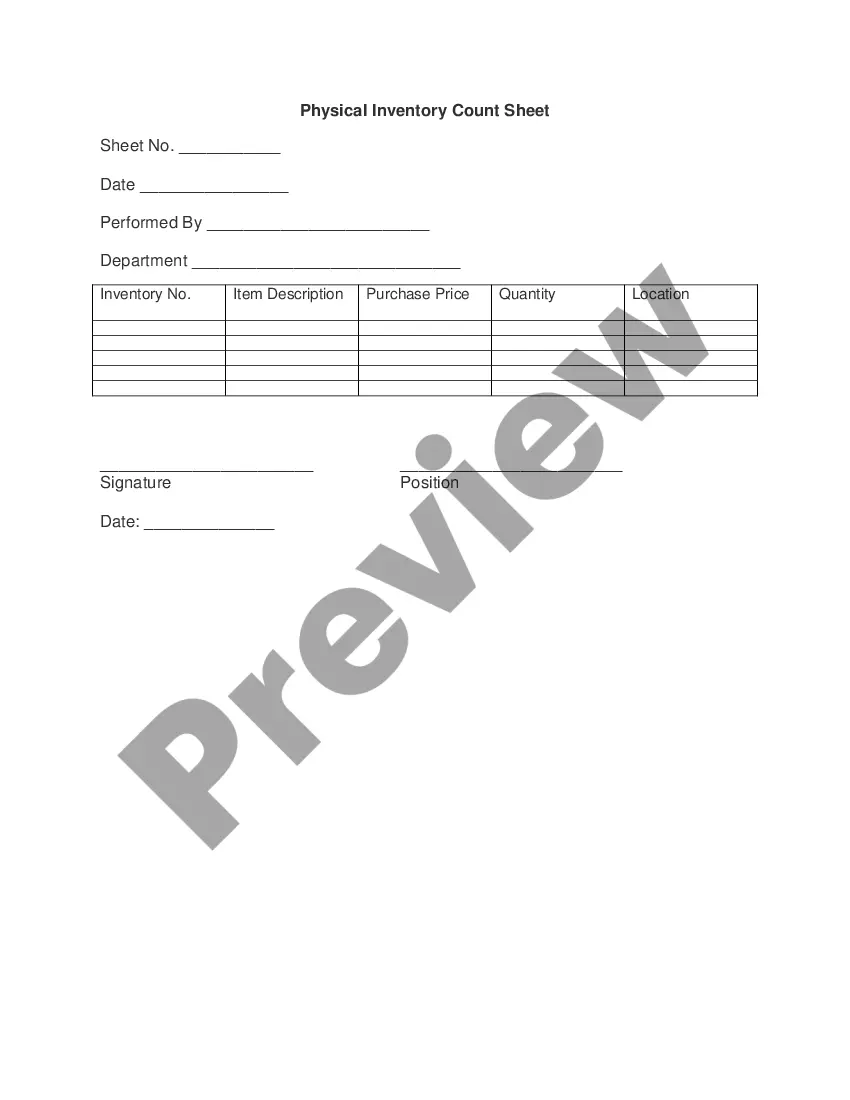

Connecticut Physical Inventory Count Sheet

Description

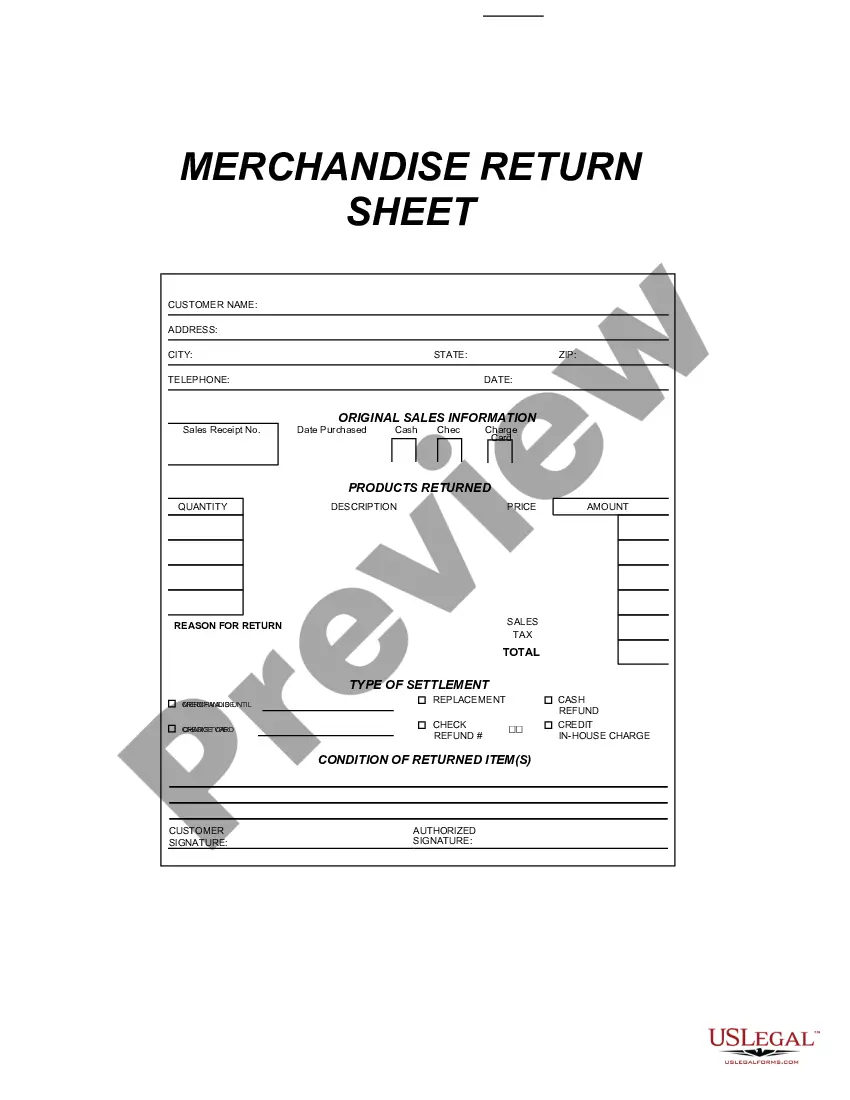

How to fill out Physical Inventory Count Sheet?

It is feasible to spend numerous hours online searching for the legal document template that complies with the state and federal requirements you need.

US Legal Forms offers a vast array of legal forms that can be examined by professionals.

You can obtain or print the Connecticut Physical Inventory Count Sheet from my services.

If available, utilize the Preview feature to look through the document template as well.

- If you already have a US Legal Forms account, you can sign in and click on the Download button.

- After that, you can complete, modify, print, or sign the Connecticut Physical Inventory Count Sheet.

- Every legal document template you purchase is yours indefinitely.

- To acquire another copy of a purchased form, navigate to the My documents tab and select the appropriate option.

- If you are visiting the US Legal Forms site for the first time, follow the simple instructions below.

- First, ensure you have selected the correct document template for the county/city you choose.

- Review the form description to verify that you have selected the right one.

Form popularity

FAQ

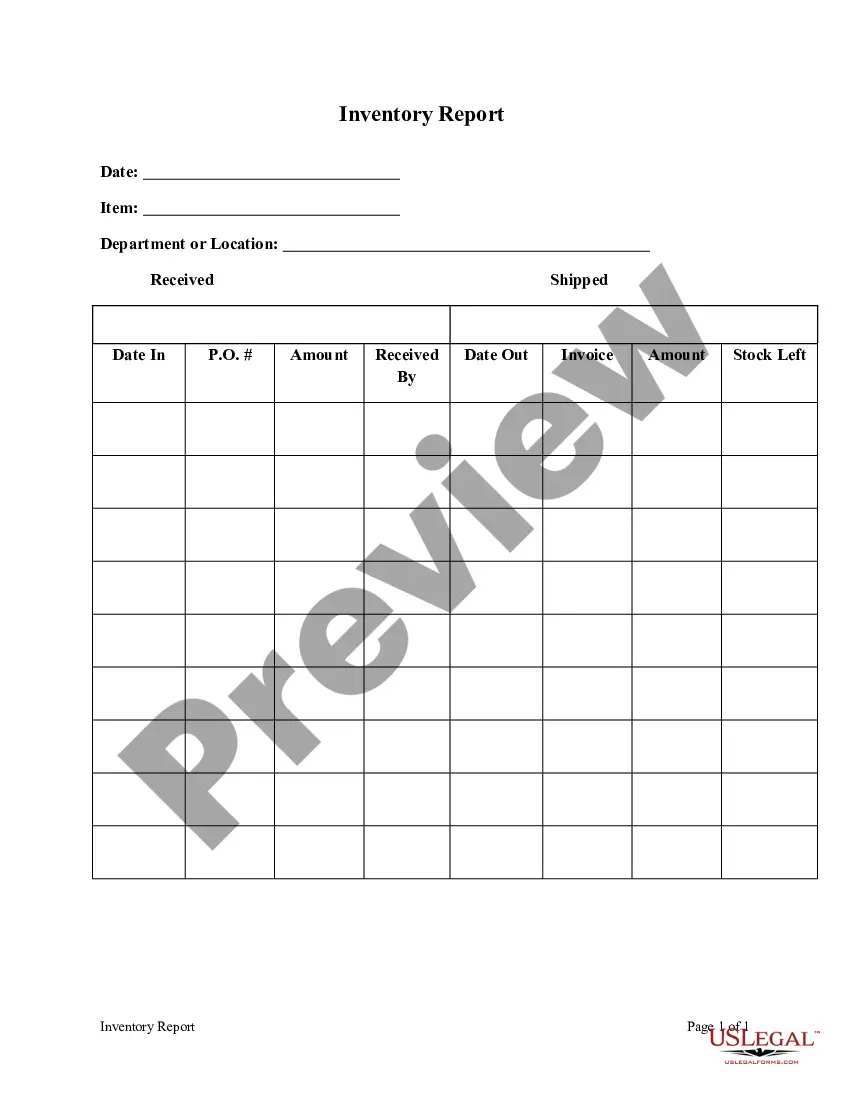

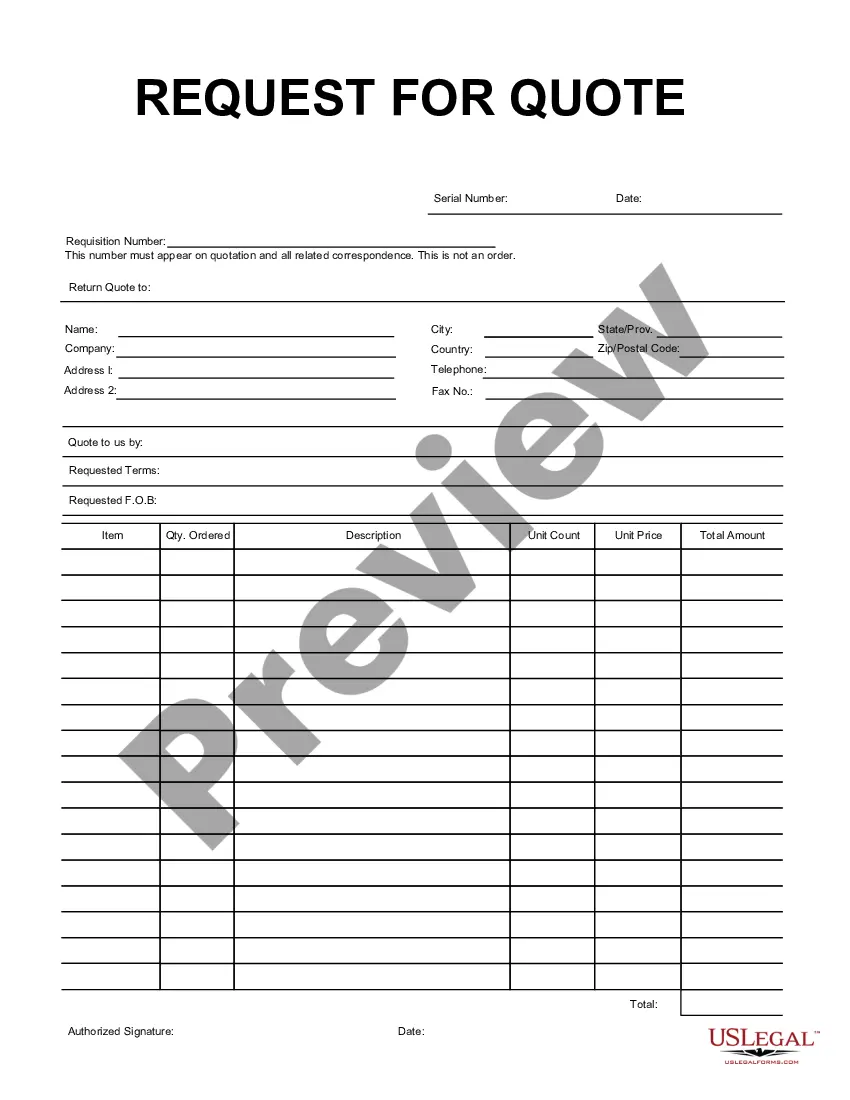

To count physical inventory, you should first prepare a detailed count sheet, such as the Connecticut Physical Inventory Count Sheet. Next, systematically count all inventory items, ensuring to double-check for accuracy. Finally, record the results on the count sheet, allowing for easier reconciliation and adjustments in inventory records.

The physical method of inventory involves counting each item in stock directly, ensuring an accurate reflection of inventory levels. This method contrasts with other methods that rely on estimates or automated tracking. Utilizing the Connecticut Physical Inventory Count Sheet can enhance this counting method by providing a clear structure for recording counts.

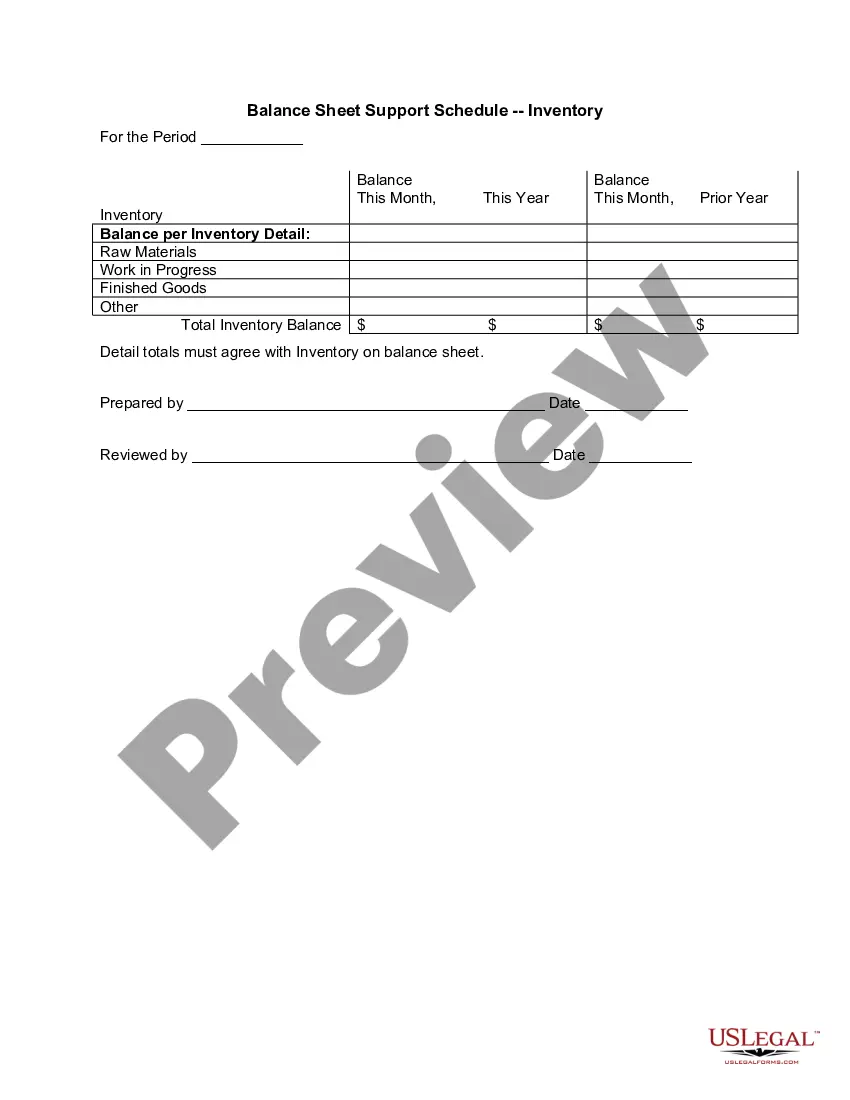

A physical inventory can typically be taken at regular intervals, such as monthly, quarterly, or annually, or during specific events such as stock audits or system upgrades. It's essential to ensure that inventory counts occur during slow periods to minimize disruption. Using the Connecticut Physical Inventory Count Sheet ensures that counts are completed efficiently and accurately.

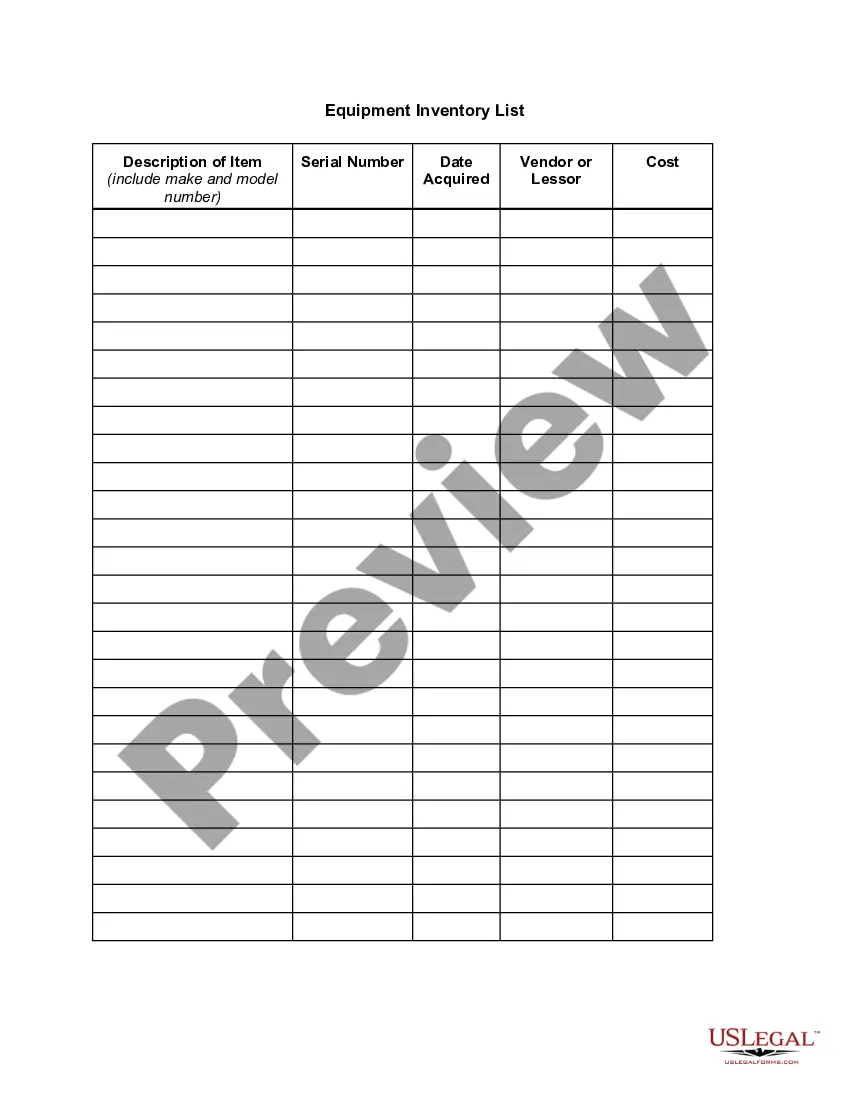

Physical inventory can be conducted at multiple levels, including site, warehouse, and even individual item levels. This flexibility helps companies maintain accurate accounting records and reflects stock availability properly. By employing the Connecticut Physical Inventory Count Sheet, businesses can streamline their counting processes for better reporting.

In SAP, physical inventory is carried out at the plant and storage location levels. This allows for a detailed and accurate inventory count, ensuring discrepancies can be identified and addressed. Utilizing the Connecticut Physical Inventory Count Sheet will facilitate this process by providing a structured format to report counts efficiently.

Inventory is typically managed at several levels, including enterprise, plant, and storage location. Each level serves a specific purpose in the overall inventory management process. For instance, at the enterprise level, organizations can track total inventory across all facilities. The Connecticut Physical Inventory Count Sheet aids in standardizing the physical count process across these levels.

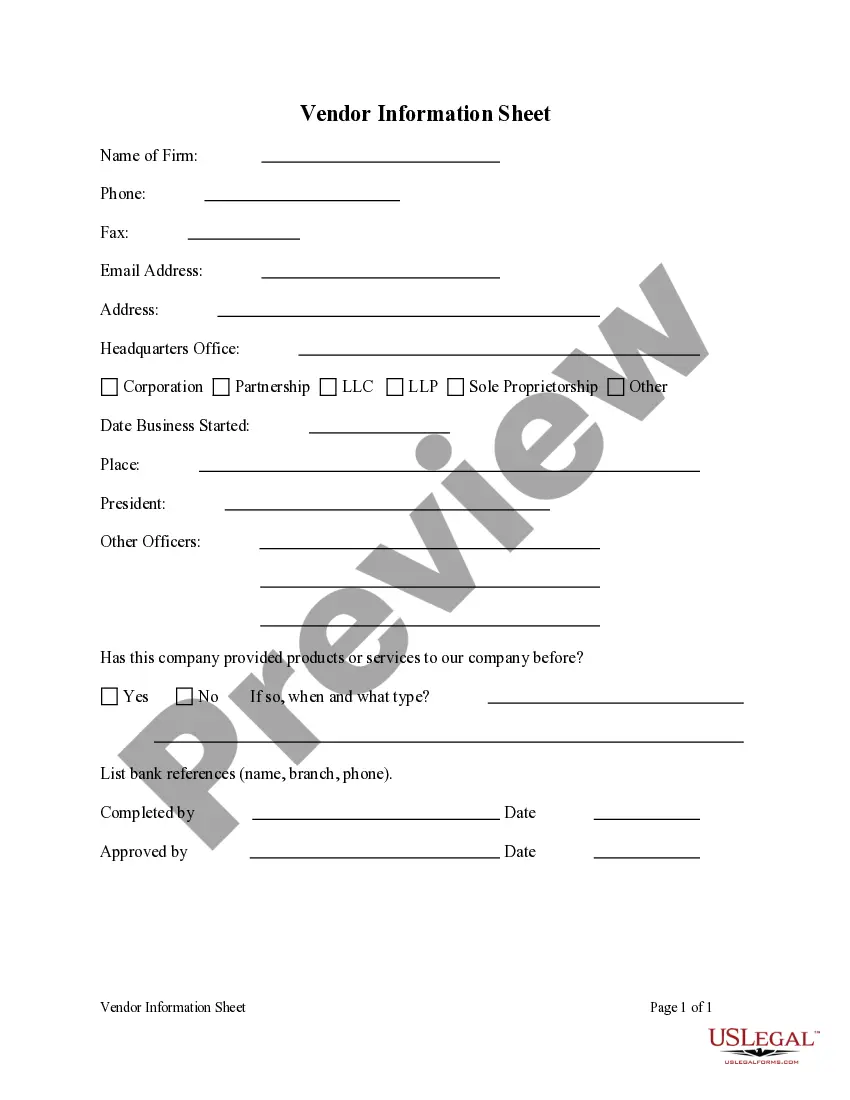

Conducting inventory records begins with maintaining a proper tracking system. Begin by utilizing tools like the Connecticut Physical Inventory Count Sheet to accurately record counts and categorize items. Regularly update your records to reflect any changes in stock levels, and reconcile these with your physical inventory checks to maintain consistency and accuracy.

One critical step in the physical count of inventory is accurate counting. Use a Connecticut Physical Inventory Count Sheet to record each item meticulously, focusing on quantities and locations. This ensures every item is counted correctly and helps in balancing your records against actual stock availability, ultimately enhancing your inventory management.

To conduct a physical inventory count effectively, begin by gathering your team and preparing your inventory count tools, including the Connecticut Physical Inventory Count Sheet. Divide the inventory area into sections, assign team members to specific areas, and start counting systematically. Lastly, verify and record all counts, ensuring accuracy in your inventory data.

Conducting a physical inventory count in QuickBooks requires a few steps. First, generate a physical inventory report to serve as your basis for comparison. Next, utilize the Connecticut Physical Inventory Count Sheet to tally actual stock and input the counts into QuickBooks. This ensures accurate financial records and streamlines future inventory tracking.