Alabama Discipline Problem Guide - Analysis and Corrective Action Plan

Description

How to fill out Discipline Problem Guide - Analysis And Corrective Action Plan?

US Legal Forms - one of the largest collections of legal documents in the United States - provides a variety of legal template documents that you can download or print.

By utilizing the website, you can discover thousands of forms for business and personal purposes, organized by categories, states, or keywords. You can locate the most recent editions of documents such as the Alabama Discipline Problem Guide - Analysis and Corrective Action Plan in just minutes.

If you currently hold a subscription, Log In and download the Alabama Discipline Problem Guide - Analysis and Corrective Action Plan from the US Legal Forms library. The Download button will appear on each form you view. You can access all previously downloaded forms within the My documents section of your account.

Make adjustments. Fill out, modify, print, and sign the downloaded Alabama Discipline Problem Guide - Analysis and Corrective Action Plan.

Each template you add to your account does not have an expiration date and is yours permanently. Therefore, if you wish to download or print another copy, simply go to the My documents section and click on the document you need. Access the Alabama Discipline Problem Guide - Analysis and Corrective Action Plan through US Legal Forms, the most extensive collection of legal document templates. Utilize a vast selection of professional and state-specific templates that fulfill your business or personal needs.

- If you are new to US Legal Forms, here are simple steps to get you started.

- Ensure that you have selected the correct form for your city/state. Click the Review button to evaluate the content of the form. Read the form description to ensure you have chosen the correct document.

- If the form does not meet your needs, use the Search field at the top of the screen to find one that does.

- If you are satisfied with the form, confirm your choice by clicking the Get now button. Then, choose your preferred pricing plan and provide your details to create an account.

- Process the payment. Use your credit card or PayPal account to complete the transaction.

- Select the format and download the document to your device.

Form popularity

FAQ

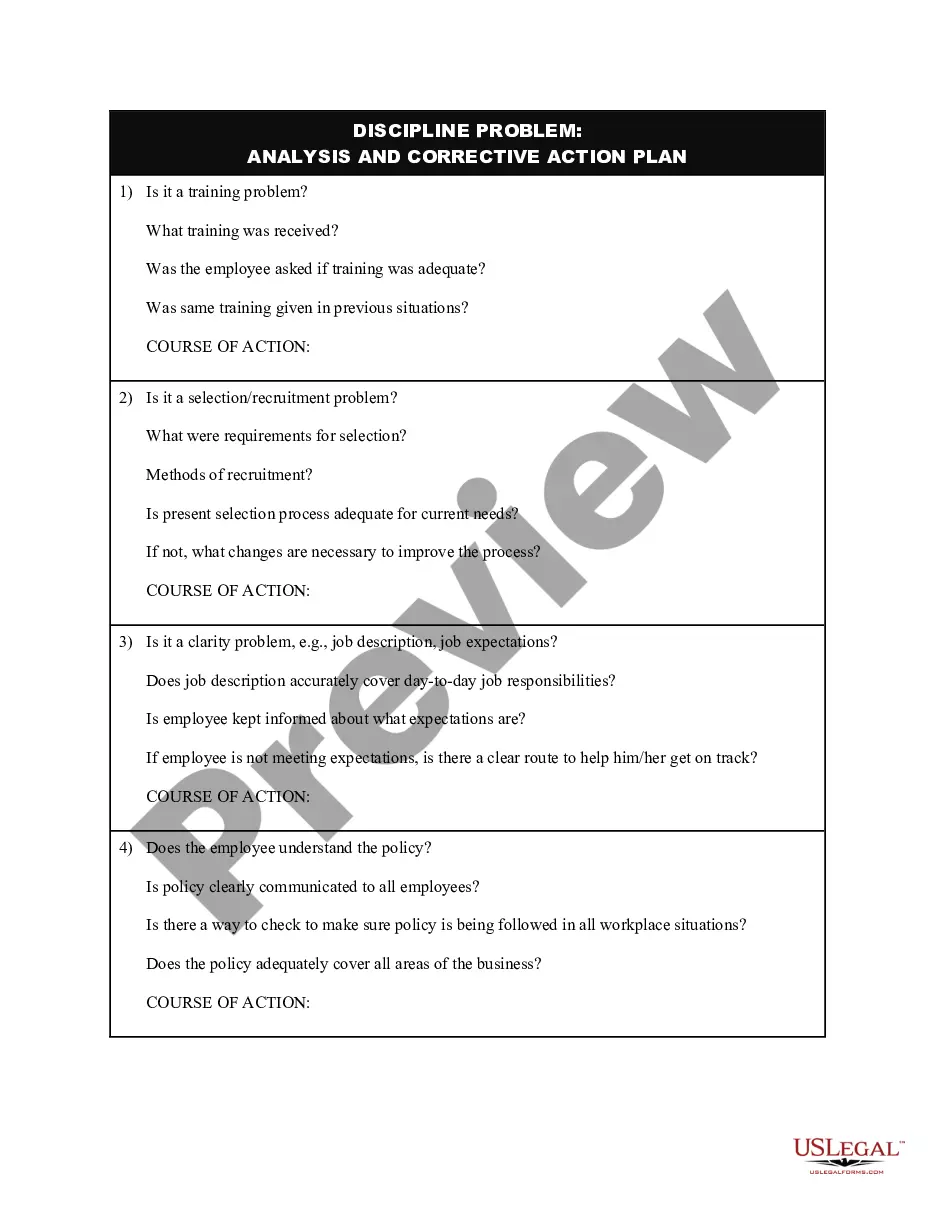

Steps to prepare CARDefine corrective action for the problem occurred.Identify the root cause.Identify when to issue CARs.Define levels of corrective action.Identify contractual requirements impacting the schedule and delivery of the products.Continuous follow ups.Recording of the end result for future reference.

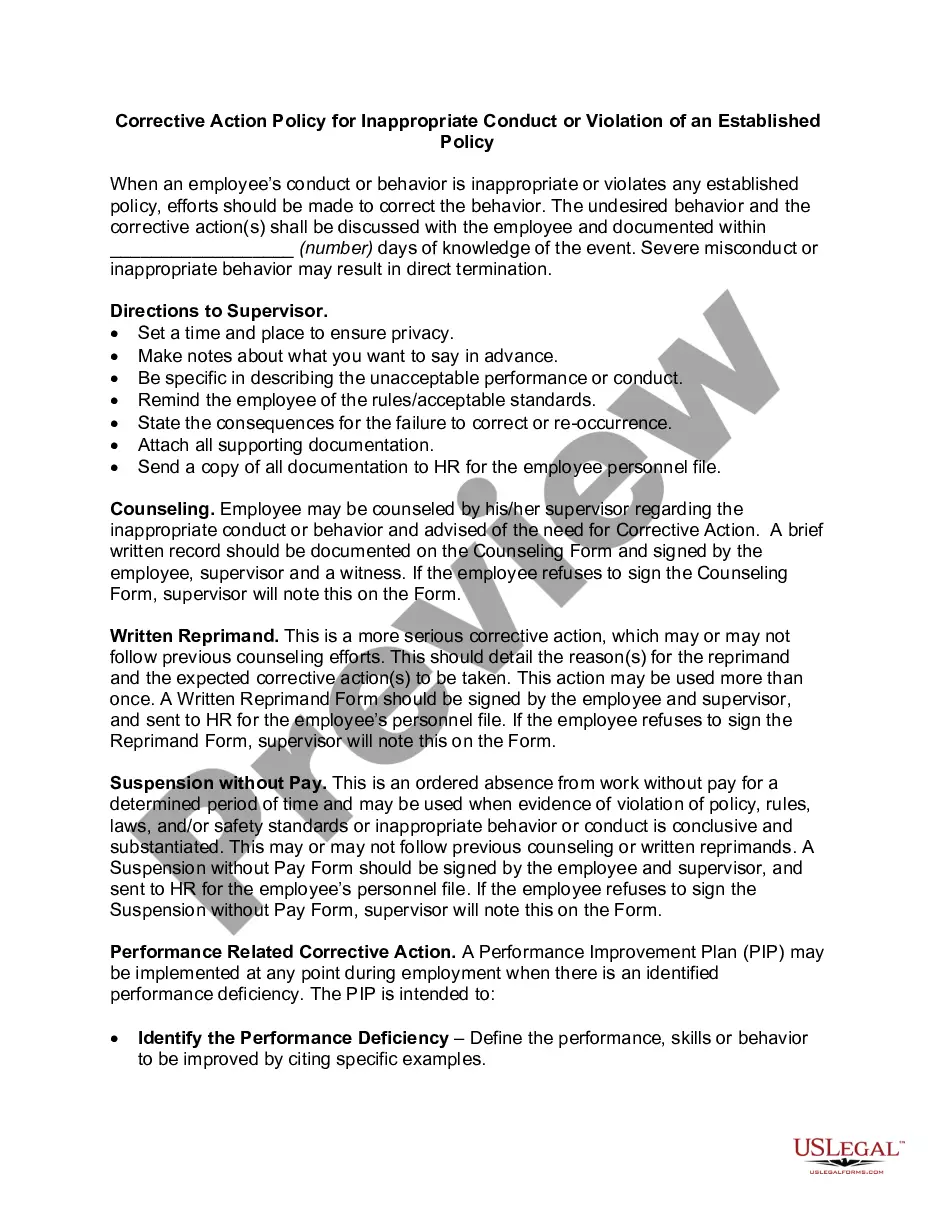

Explain clearly why the behavior or performance is a concern, including how it is impacting operations and other employees. Use direct and descriptive examples. Explain clearly the expected performance or behavior. Describe what will happen next if the performance is not corrected.

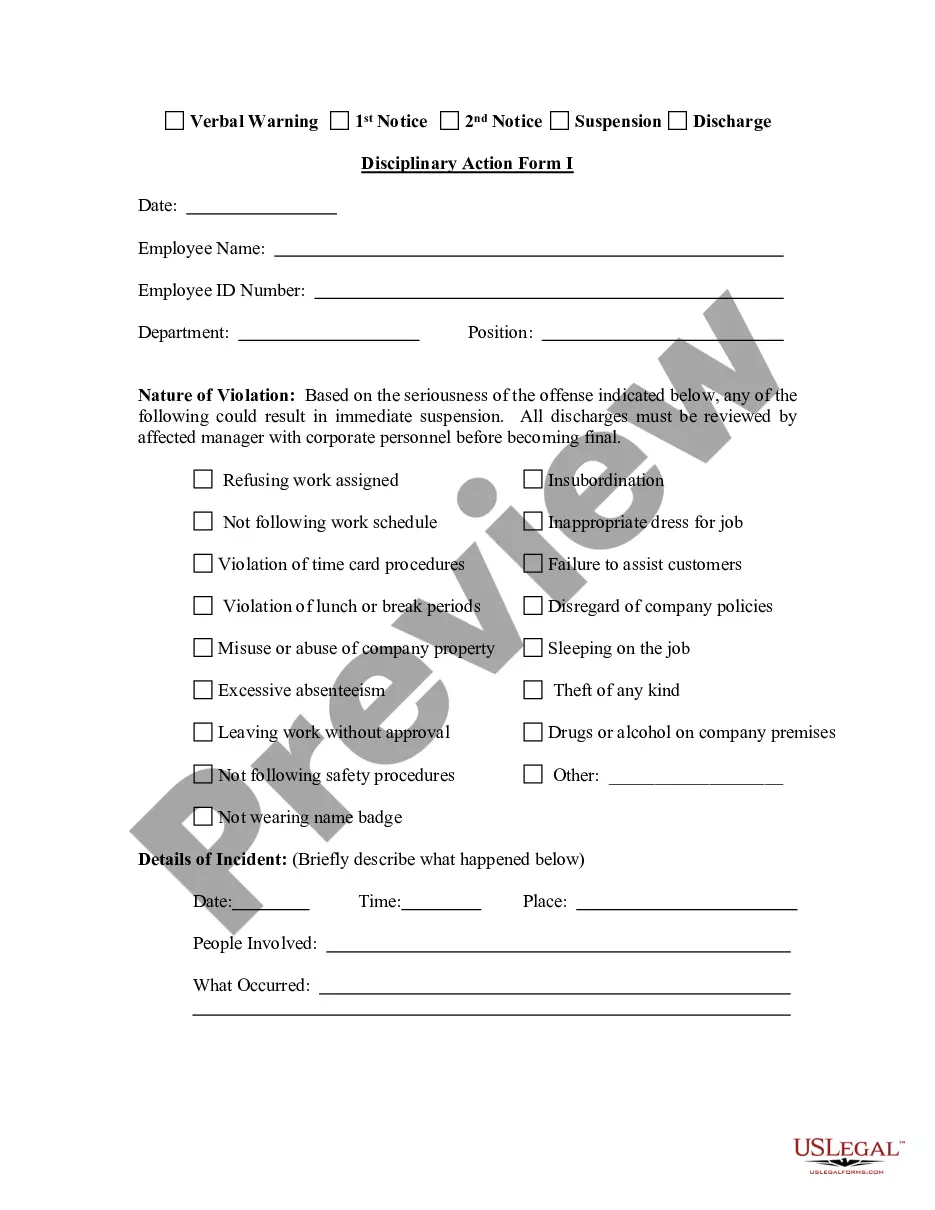

What to include in a disciplinary action formFirst and last name of the employee.Date of the incident.Summary of the issue or event, including witnesses, location, times and dates.Past events or behavior relating to current violation.Employee comments.Corrective actions and dates.More items...?

Here are some headings that should appear in any corrective action / accident form that you keep a record.Step 1: Clearly Describe Problem.Step 2: Immediately Stop Problem Accelerating (Commonly Referred To As Containment Action)Step 3: Establish What Caused Problem (Commonly Referred To As 'Root Cause')More items...?

Depending on the severity of the case, a disciplinary action can take different forms, including:A verbal warning.A written warning.A poor performance review or evaluation.A performance improvement plan.A reduction in rank or pay.Termination.

How do you deliver a disciplinary action?Review the employee's file and performance records.Prepare for the employee discussion.Hold a meeting with the employee.State objectives of the disciplinary action.Ask for the employee's input.Provide a copy of the disciplinary action to the employee.Schedule a follow-up.

What Should Be in a Corrective Action Form?Information about the employee, including his name, the date and the name of his supervisor.Details about the rule violation that occurred.Details about the violation, such as the date and time and the place it occurred.The supervisor's statement about the incident.More items...

Corrective action plans also include the metrics for completion or baseline for the company to reach to consider the issue resolved. For example, the company experiencing an upset customer from their broken item may look to have a satisfied customer as their metric for completion.

Some examples of immediate corrective actions are: throwing out food items that show signs of spoilage (e.g. bad smell, slimy skin) rejecting a food delivery with bite marks on the packaging (or other signs of pest infestation) transferring unrefrigerated perishable food items into cold storage (5°C or below)