Dissolution Technologies

Description

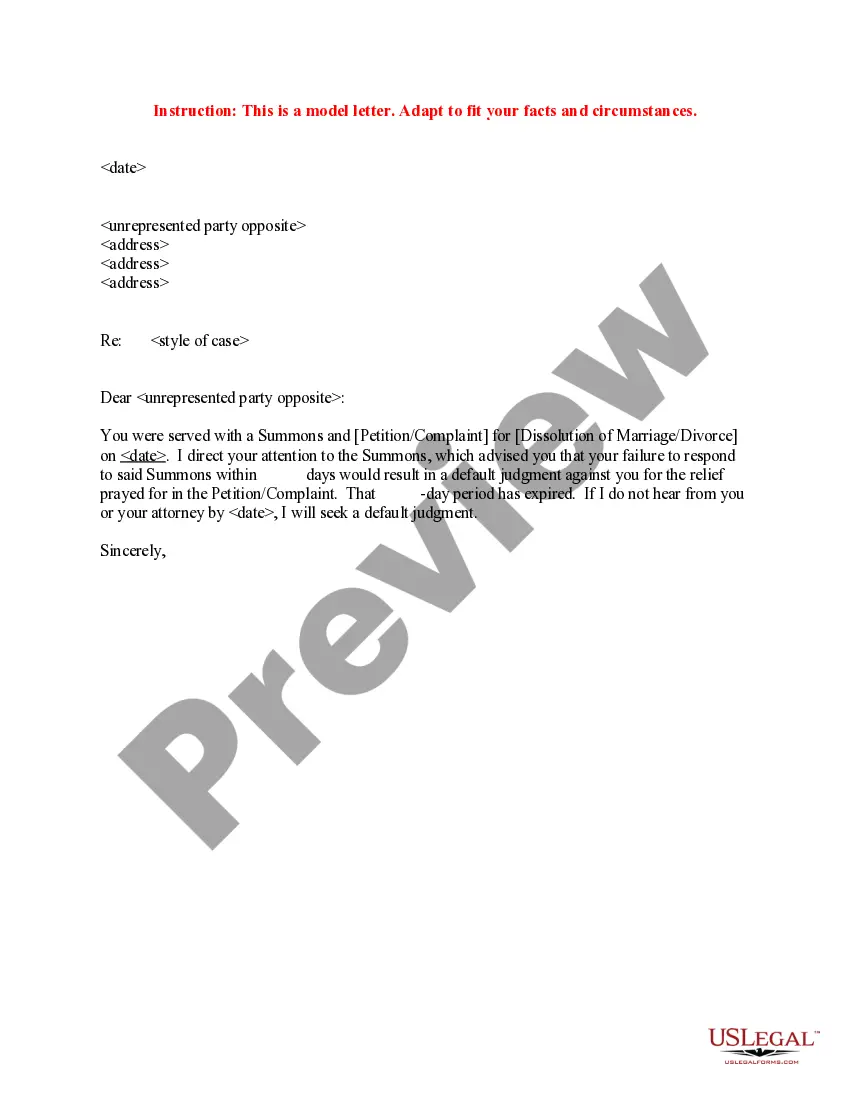

How to fill out Sample Letter To Unrepresented Party Opposite Regarding Respond To Dissolution - Divorce Petition - Complaint Or Suffer Default?

- If you’re a returning user, log in to your account to download the required form template by clicking the 'Download' button. Ensure your subscription is active; if not, renew it as per your selected plan.

- For first-time users, begin by browsing the extensive form library. Preview templates to confirm they meet your needs and adhere to local jurisdiction requirements.

- If necessary, utilize the search function to find alternative templates that may better fit your situation. Proceed only when you have selected the correct one.

- Once you’ve chosen your document, click 'Buy Now' to select your preferred subscription plan and create your account for access.

- Complete your purchase by entering your payment details through credit card or PayPal. Once the payment is processed, you will have access to your document.

- Download the desired form to your device for completion. You can also find this document anytime in the My Forms section of your profile.

With US Legal Forms, you benefit from an extensive library and the support of premium experts, ensuring your documents are accurate and legally sound. Enjoy a seamless experience with a tool that offers more forms than competitors for a similar price.

Start simplifying your legal document needs today by exploring US Legal Forms!

Form popularity

FAQ

To perform a dissolution test, you'll need to prepare the dosage form and configure the apparatus according to specific guidelines. Following established protocols for the dissolution media, temperature, and agitation speed is crucial. Using reliable dissolution technologies can streamline the testing process and improve accuracy, facilitating better product development and testing outcomes.

Several manufacturers specialize in producing dissolution testing equipment, including well-known brands in the pharmaceutical industry. These manufacturers design their products to meet various testing requirements and regulatory standards. Partnering with companies that utilize advanced dissolution technologies ensures you have access to the latest innovations in the field.

The most commonly used dissolution apparatus is the paddle or basket method, which simulates how a drug dissolves in the human body. These methods allow for precise and reliable measurements, leading to consistent batch-to-batch quality. Incorporating modern dissolution technologies can enhance the accuracy and reliability of your results.

Choosing the right dissolution media is essential for accurate testing and results. Factors such as the solubility of the drug, physiological relevance, and regulatory guidelines will influence your media selection. Consulting with experts in dissolution technologies can streamline this process and enhance your testing efficiency.

The USP dissolution test follows guidelines set by the United States Pharmacopeia to evaluate how a drug dissolves under controlled conditions. It provides a reliable and standardized method to assess the quality of pharmaceutical products. Utilizing advanced dissolution technologies, these tests ensure products meet necessary quality standards, supporting their safety and efficacy.

The standard dissolution test measures how quickly and completely a drug dissolves in a specific solution. This test helps determine the release of active ingredients from a dosage form, which is crucial for ensuring the effectiveness of the medication. Dissolution technologies play a vital role in this process, enabling consistent results that can inform product development and regulatory compliance.

To set a dissolution apparatus, you need to consider the type of dosage form and comply with the relevant regulatory guidelines. Common factors include the choice of apparatus type, speed of rotation, and temperature settings. Employing advanced dissolution technologies can simplify this process, ensuring that your apparatus is correctly configured for optimal performance.

Selecting the appropriate dissolution media involves considering the solubility characteristics of your active ingredient, the pH level that mimics physiological conditions, and regulatory guidelines. Dissolution technologies provide guidance on optimizing media selection to better predict in vivo performance. It's essential for enhancing the development of your formulation.

The acceptable relative standard deviation (RSD) for dissolution tests typically ranges between 5% to 10% depending on product type and regulatory expectations. Maintaining a low RSD indicates consistent and reliable dissolution performance. Incorporating advanced dissolution technologies can help you achieve this standard, ensuring quality control.

Dissolution specifications define the acceptable limits for the release of active substances from a dosage form. They are critical for ensuring product quality and therapeutic effectiveness. By leveraging dissolution technologies, you can create clear and accurate specifications that meet regulatory standards.