Performance Agreement For Supply Chain Manager In Orange

Description

Form popularity

FAQ

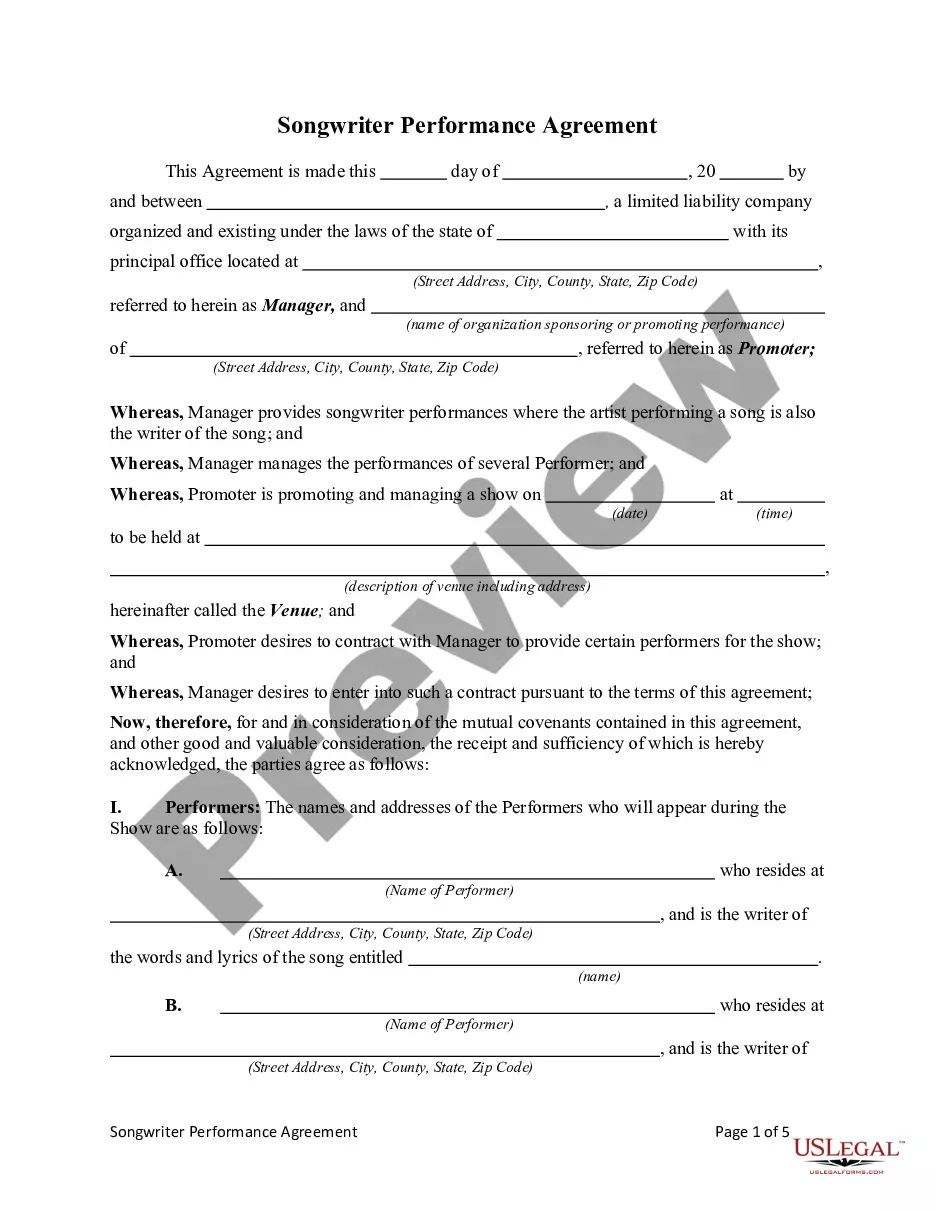

Performance Agreement: An arrangement between an employer and an employee, or a business and a contractor, which outlines the terms, expectations, goals, and standards of performance for each party. Scope: The range of activities, duties, and expectations covered by an agreement.

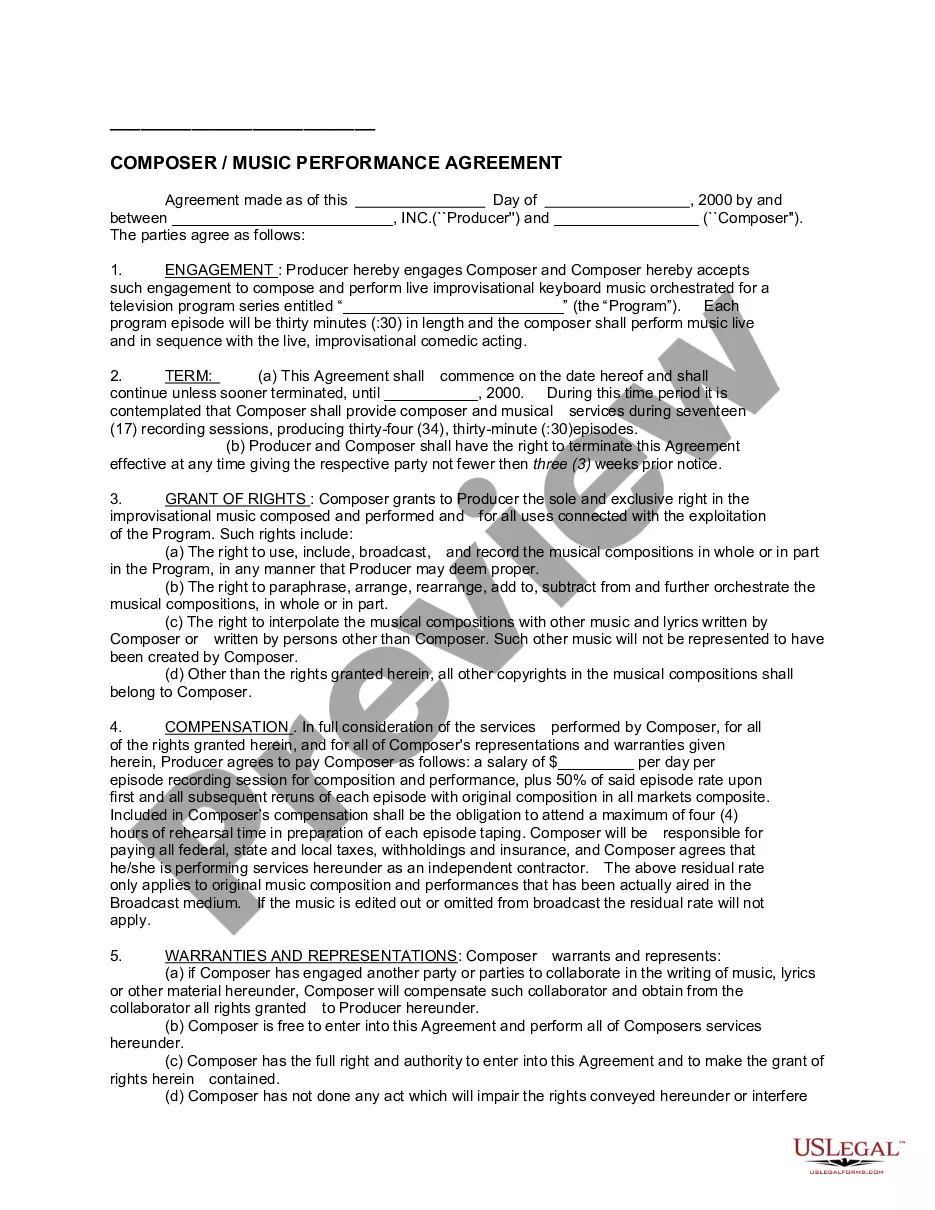

Contract logistics refers to the outsourcing of resource management tasks by one company to a third-party company specializing in logistical matters, such as transportation, warehousing, and order fulfillment.

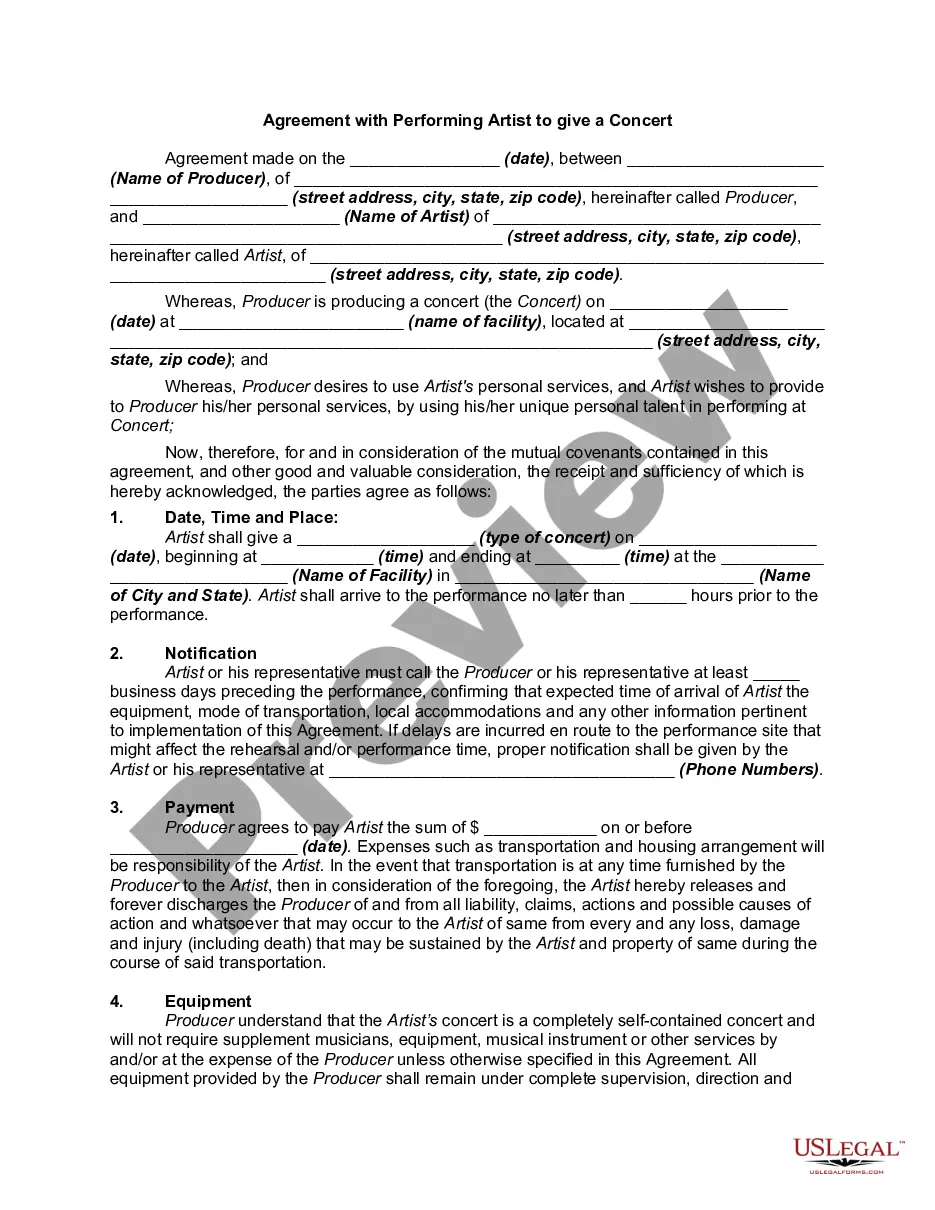

A supply contract is an agreement outlining the way in which one party, the supplier, supplies, sells or distributes goods to another party, the customer. Supply contracts are specifically negotiated and drafted for a particular job/transaction and often include finer detail than terms of trade agreements.

Chain of contracts means the contracts be- tween the owner and the contractor, the contractor and any subcontractor or materialman, the subcontractor and any sub-subcontractor or materialman, and the sub-subcontractor and any materialman.

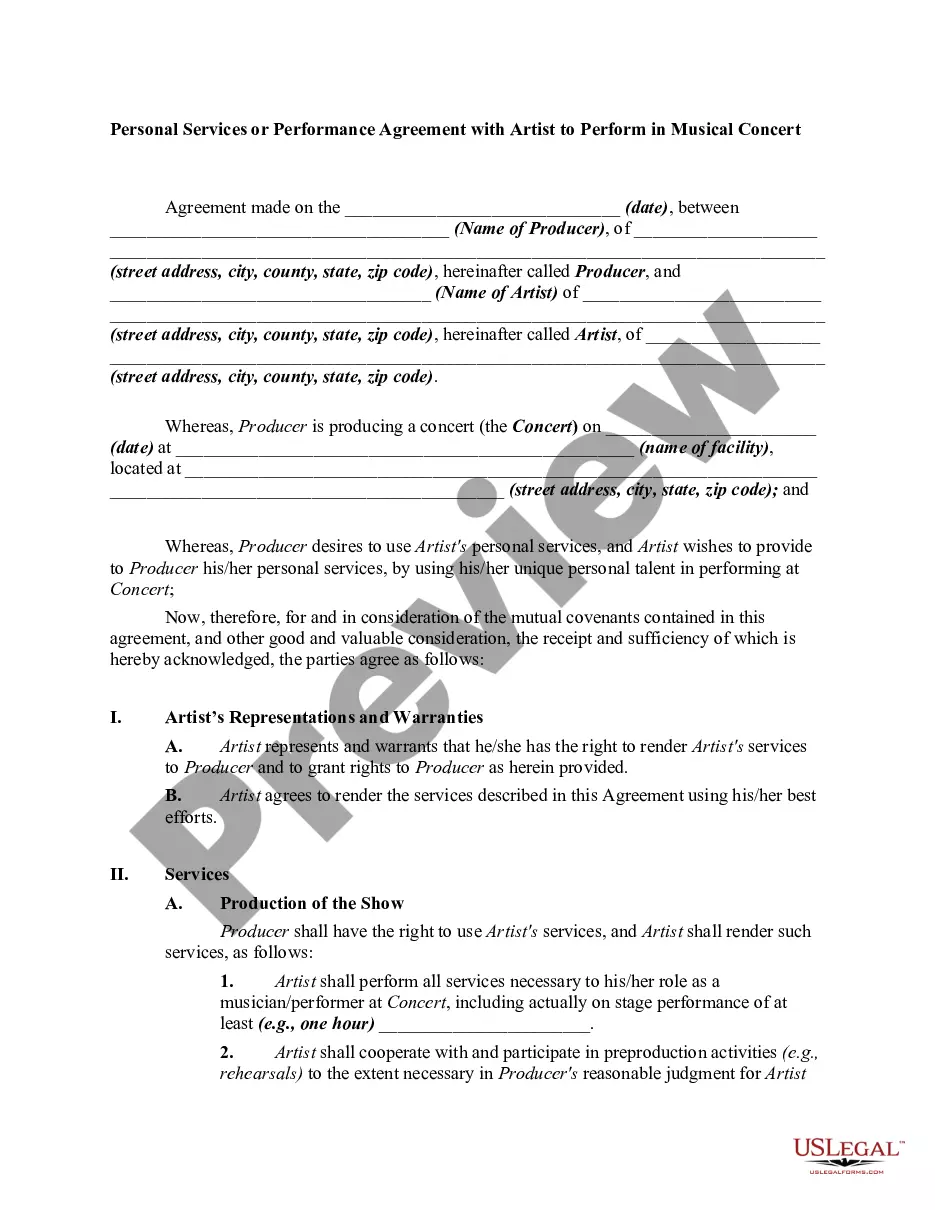

In supply chain management, contracts define the parameters of performance, quality, and delivery. These terms legally bind different organizations in the supply chain network.

The performance management system entails processes that are critical to improving supply chain effectiveness and efficiency including identifying measures and data requirements, defining targets, planning, communicating, measuring, reporting and feedback.

10 key benefits of supply chain management Improve your operational efficiency. Gain better financial visibility and insights. Make smarter purchasing decisions. Reduce total manufacturing costs. Reduce inventory carrying costs and storage requirements. Improve customer satisfaction and brand credibility.

A service-level agreement (SLA) is a contract between a logistics service provider and a customer that specifies, usually in measurable terms, what services the logistics service provider will furnish. Many logistics service providers will provide their customers with an SLA.

Here are six steps to consider when creating your supply chain plan: Review company goals. Perform market research. Forecast consumer demand. Allocate inventory requirements. Fulfill consumer orders. Ensure planning flexibility.

Firstly, an efficient supply chain optimizes internal processes such as inventory management and production planning. This helps to minimize the costs and lead times associated with these activities, thus improving the company's overall profitability.