Lean Construction Mrv

Description

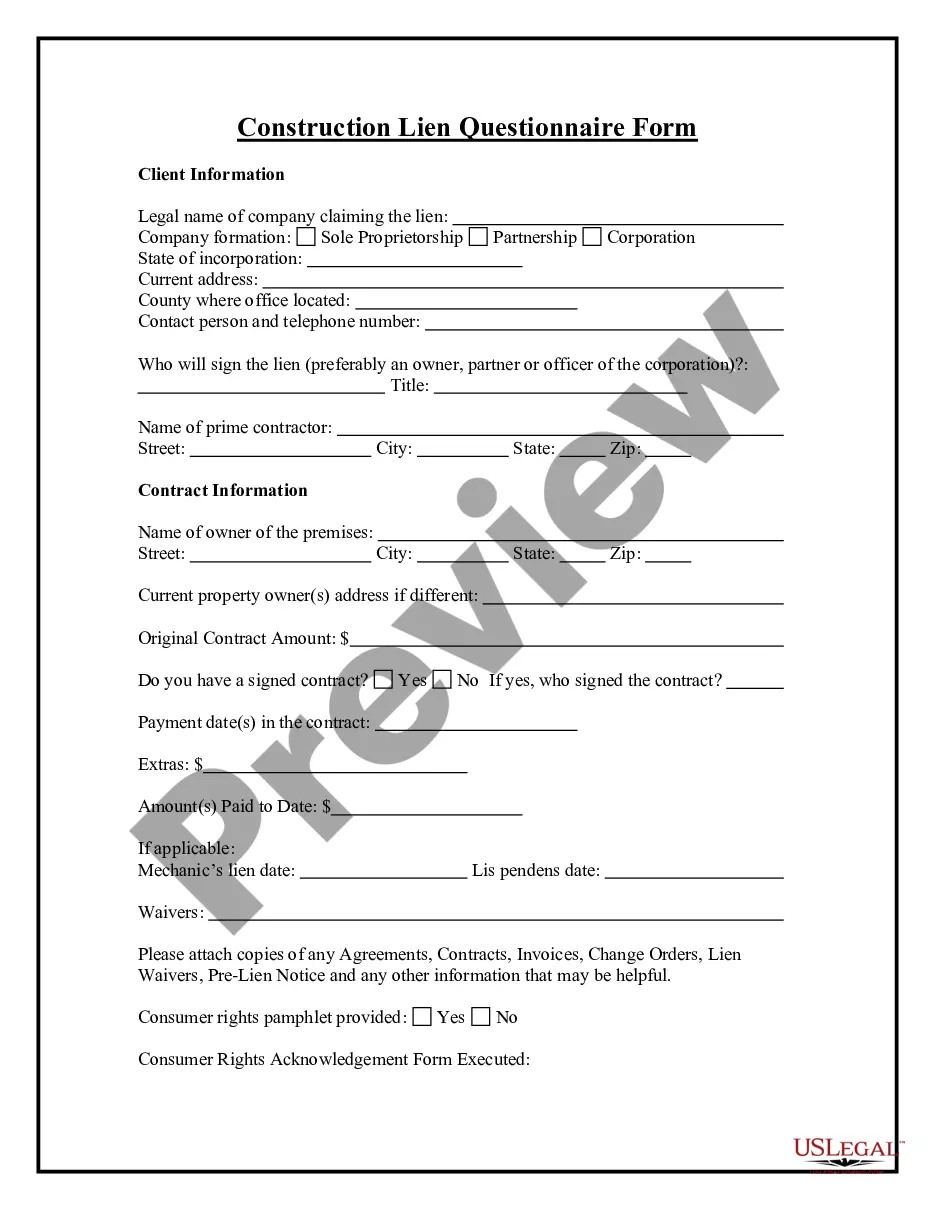

How to fill out South Dakota Construction Or Mechanics Lien Package - Individual?

- Log in to your account on the US Legal Forms website. Ensure your subscription is active to access your files.

- If you're a new user, check the Preview mode and form description for the lean construction mrv template that suits your requirements.

- Utilize the Search tab to find additional templates if necessary. Ensure the selected form meets your local jurisdiction needs.

- Click the 'Buy Now' button for the document you need, and select your preferred subscription plan.

- Complete the purchase by entering your credit card details or using your PayPal account for payment.

- Download the completed form directly to your device. You can also access it anytime from the 'My Forms' section of your profile.

Following these simple steps not only saves time but ensures you have the right legal documents at your fingertips with minimal hassle.

Start your journey with US Legal Forms today and experience the benefits of an extensive library of legal documents that empower you and your clients. Don't miss out on making your legal processes simpler!

Form popularity

FAQ

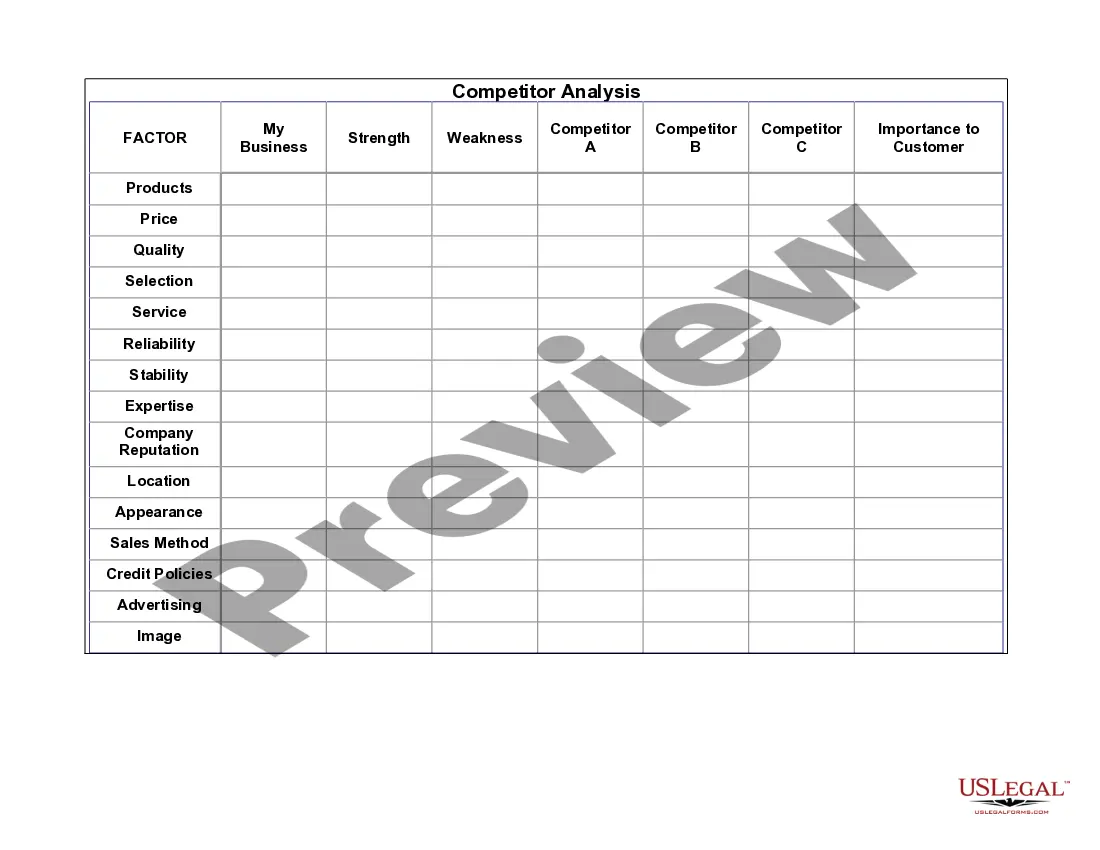

Visual management is a technique used in lean practices to create an easily understandable visual representation of workflows and metrics. This method enables teams to quickly identify issues and track performance. Incorporating visual management within lean construction mrv fosters transparency and ensures that everyone is aligned towards project goals.

Lean BIM refers to the integration of Lean principles with Building Information Modeling. This combination streamlines workflows and enhances collaboration among stakeholders. By implementing lean construction mrv with BIM, teams can achieve a higher degree of efficiency, reduce errors, and improve project outcomes.

A main objective of lean construction is to deliver maximum value to the customer while minimizing waste. This goal helps in providing better quality work at reduced costs and with faster timelines. Lean construction mrv aims to align the interests of all parties involved, resulting in projects that satisfy clients and improve overall performance.

The two main principles of lean manufacturing are reducing waste and increasing efficiency. These principles promote a culture of continuous improvement, where teams actively seek out ways to streamline processes. When applied in the context of lean construction mrv, these principles help construction professionals deliver projects on time and on budget.

Lean construction is built on several key principles, including collaboration, continuous improvement, and maximizing value. These principles encourage teams to work together closely and continuously evaluate processes to find improvements. By applying these principles in lean construction mrv, organizations can achieve enhanced project outcomes and client satisfaction.

The most basic principle of lean is to identify and eliminate waste in all forms. This includes wasted time, materials, and labor. Embracing this principle within lean construction mrv can lead to smoother operations and reduced costs, allowing for better use of resources in construction projects.

The main principle of lean construction is to minimize waste while maximizing productivity. This principle focuses on delivering value to the client by streamlining processes and improving efficiency. By applying lean construction mrv, projects can be completed faster and with fewer resources, ultimately benefiting both clients and contractors.

To implement lean construction mrv, start by assessing your project's value streams and identifying areas of waste. Engage all team members in open communication and collaboration to derive solutions together. Regularly review processes to promote continuous improvement and ensure projects stay on track and under budget.

The five lean practices in lean construction mrv include defining value from the client's perspective, mapping the value stream, creating flow by eliminating waste, establishing pull systems, and continuously improving through learning. These practices foster a culture of efficiency, leading to better project outcomes. By implementing these practices, you ensure a more organized workflow.

To calculate value stream mapping in the context of lean construction mrv, start by outlining all actions involved in your process from start to finish. Then, assess each step to identify value-adding activities and wasteful steps. This analysis helps you streamline your processes and improve overall efficiency.