Get Stud Welding Procedure Qualification 2020-2026

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Stud Welding Procedure Qualification online

Filling out the Stud Welding Procedure Qualification form online can streamline the process of documenting your welding qualifications. This guide provides step-by-step instructions to ensure you accurately complete each section of the form, making it user-friendly for individuals with varying levels of experience.

Follow the steps to effectively complete the qualification form.

- Click ‘Get Form’ button to obtain the form and open it in your preferred online editor.

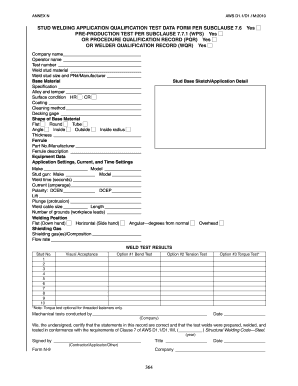

- Begin by filling in the company name and the operator's name in the designated fields at the top of the form.

- Enter the test number, specifying the unique identification for the welding procedure qualification test.

- Provide details about the weld stud material, including the specific type of material used.

- Fill in the size and part number or manufacturer of the weld stud in the appropriate fields.

- For base material information, enter the specification along with details about the alloy and temper.

- Indicate the surface condition of the base material by checking HR or CR, and specify any coating present.

- Describe the cleaning method used prior to welding and enter the decking gauge measurement.

- Choose the shape of the base material from the provided options such as flat, round, or tube.

- Fill in the thickness of the base material and provide the part number and manufacturer for the ferrule.

- In the equipment data section, record application settings and the specifications of the stud gun, including brand and model.

- Enter the weld time in seconds, current in amperage, and specify the polarity used for the welding process.

- Document the lift and plunge measurements, along with the weld cable size and length.

- Specify the number of grounds for workpiece leads included in the setup.

- Select the welding position from options such as flat, horizontal, or angular and provide details about the shielding gas and flow rate.

- Record the weld test results, including options for visual acceptance, bend test, and any additional tests performed.

- Have the designated person certify that the statements made are correct by filling in their name, title, and the date of signing.

- Upon completing the form, you can save your changes, download a copy, print it for records, or share it as needed.

Complete your Stud Welding Procedure Qualification form online today to ensure a thorough documentation process.

Tolerance in stud welding refers to the allowable variations in dimensions and characteristics of welded joints. It is essential to adhere to specific tolerances to ensure structural integrity and quality. By following established tolerances during the stud welding procedure qualification, you can promote reliability and performance in your projects.

Industry-leading security and compliance

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.