Get Gear Failure Analysis

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Gear Failure Analysis online

Filling out the Gear Failure Analysis form is a key step in ensuring your participation in the seminar. This guide provides you with clear and detailed instructions on how to complete each section of the form effectively.

Follow the steps to complete your Gear Failure Analysis form.

- Click 'Get Form' button to obtain the form and open it in the editor.

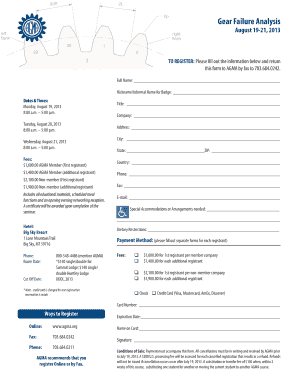

- In the 'Full Name' field, enter your complete legal name. This is important for registration confirmation and certificate issuance.

- Fill in your 'Nickname/Informal Name for Badge' as you would like it to appear on your name badge during the seminar.

- Provide the dates and times of attendance, which are from August 19 to August 21, 2013, with the timings listed on the form.

- Select your registration fee based on your membership status, filling in the appropriate fee next to either 'AGMA Member' or 'Non-member'.

- Complete the 'Title' and 'Company' fields to indicate your professional role and organization.

- Fill out your contact information, including 'Address', 'City', 'State', 'ZIP', and 'Country', ensuring all details are accurate.

- Enter your 'Phone' and 'Fax' numbers where you can be reached.

- Provide your email address in the 'E-mail' field for confirmation and further communication regarding the seminar.

- If you require any special accommodations, indicate these in the 'Special Accommodations or Arrangements needed' section.

- List your 'Dietary Restrictions' as necessary to ensure appropriate meal options are provided.

- Choose your preferred 'Payment Method', noting the details required for credit card payments, including card number and expiration date.

- Review all inputs for accuracy before finalizing your registration.

- Upon completing the form, save your changes, download a copy for your records, or choose to print the form directly.

- Once completed, submit the form as per the guidelines provided, ensuring it reaches the appropriate AGMA contact.

Complete your Gear Failure Analysis form online today for a seamless registration experience.

Gears can experience various types of failures, including wear, breakage, and misalignment. Common issues might arise from insufficient lubrication, excessive loads, or manufacturing defects. Understanding these failures is essential in conducting a Gear Failure Analysis, which can help you design better systems and select appropriate materials for your applications. By using resources like US Legal Forms, you can find the necessary guidelines to address these challenges effectively.

Industry-leading security and compliance

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.