Get Lanl Wps 3-01 2006-2025

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the LANL WPS 3-01 online

Filling out the LANL WPS 3-01 form is an essential step in documenting your welding procedures. This guide provides clear and supportive instructions to help you complete the form accurately and efficiently online.

Follow the steps to successfully complete the LANL WPS 3-01 form online.

- Use the ‘Get Form’ button to access the LANL WPS 3-01 form and open it in your preferred online editor.

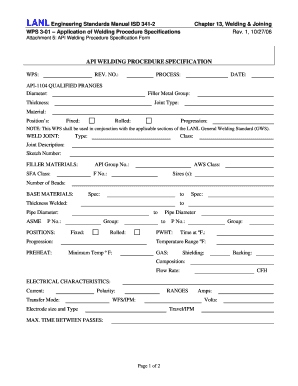

- Fill in the WPS number and revision number at the top of the form. Ensure accuracy as these details are crucial for identification and record-keeping.

- Complete the API-1104 qualified ranges section. Enter the diameter, process, filler metal group, thickness, joint type, material, and position information in the designated fields.

- In the weld joint section, specify the type, class, joint description, and sketch number. This detail is critical for understanding the weld configuration.

- Fill out the filler materials section, including API group number, SFA class, AWS class, F number, sizes, and the number of beads as necessary.

- Provide the base materials details, specifying the specification, thickness welded, pipe diameter, and relevant ASME and P numbers.

- Complete the positions section, confirming groups, whether fixed or rolled, and the progression details.

- Enter the preheat specification and the relevant pipe diameter and P number, along with post-weld heat treatment (PWHT) information, including group, time, and temperature ranges.

- Fill in the gas section, detailing the shielding type, backing composition, and flow rate in CFH.

- Provide the electrical characteristics, including current, polarity, transfer mode, WFS/IPM, amps, volts, electrode size, and type.

- Indicate the welding technique, such as whether you are using a line-up clamp, and specify if the bead will be stringer or weave. Also, clarify if the connection will be a single pass or multi-pass.

- Complete the joint sketch and bead number section, noting the number of passes and layer sequence to represent the welding operation accurately.

- Finally, fill in the prepared by and approved by sections, including the relevant dates, to ensure proper documentation.

- Once you have completed all fields, save your changes, and choose to download, print, or share the form as needed.

Begin filling out your LANL WPS 3-01 online today for accurate welding documentation.

Related links form

The WPS standard serves as a guideline to ensure welding procedures are consistent, safe, and effective across various projects. Specifically, for LANL WPS 3-01, it outlines the accepted practices and standards that need to be followed during welding activities. Adhering to these standards helps in achieving quality results while meeting regulatory requirements. By using a recognized WPS standard, organizations can reduce the risk of defects and ensure compliance.

Industry-leading security and compliance

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.