Loading

Get Electronic/mechanical Line Leak Detector Annual Functionality - Dsps Wi

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Electronic/Mechanical Line Leak Detector Annual Functionality - Dsps Wi online

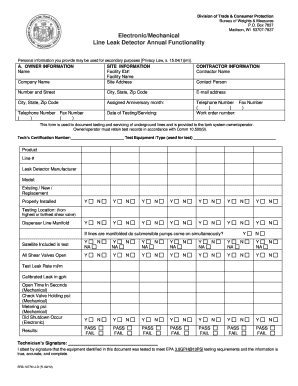

Filling out the Electronic/Mechanical Line Leak Detector Annual Functionality - Dsps Wi form is an essential process for documenting the testing and servicing of underground line leak detection systems. This guide aims to provide you with clear, step-by-step instructions to navigate the online form effectively.

Follow the steps to complete your annual functionality form

- Press the ‘Get Form’ button to access the form and open it for editing.

- Begin by entering the owner information. Provide the owner's name in the designated field.

- Next, complete the contractor information. Fill in the contractor's name and the company name associated with the testing.

- In the site information section, enter the facility ID number, facility name, and the complete site address including number, street, city, state, and zip code.

- Add the email address and the telephone number of the site contact. You may also include their fax number if applicable.

- Indicate the assigned anniversary month for the testing.

- Record the date of testing or servicing in the specified field.

- Enter the work order number in the adjacent field to document the task.

- Provide the name of the contact person who facilitated the testing.

- Insert the technician’s certification number and the type of test equipment used.

- List the product line number and leak detector manufacturer, along with the model information for the equipment tested.

- Specify whether the leak detector is new, existing, or a replacement and indicate if it was properly installed by selecting 'Y' for yes or 'N' for no.

- Identify the testing location from the highest or farthest shear valve and note whether submersible pumps activated simultaneously during the test.

- Answer the questions regarding the testing conditions, including if all shear valves were open and detail the test leak rate, calibrated leak in gallons per hour, open time in seconds, check valve holding pressure, and metering pressure for mechanical systems.

- Indicate if a shutdown occurred during electronic testing and document the results for each testing parameter as pass or fail.

- Finalize the form by obtaining the technician's signature to affirm the information’s accuracy and compliance with EPA testing requirements.

- After completing the form, ensure you review all entries for accuracy, then save your changes, download, print, or share the form as necessary.

Complete your Electronic/Mechanical Line Leak Detector Annual Functionality - Dsps Wi form online today!

A mechanical line leak detector should be installed in the submersible turbine pump head, which is typically in a sump or pit above the tank. The leak detector automatically tests for piping leaks downstream each time the pump is turned on by monitoring how long it takes for the line to reach operating pressure.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.