Get Prestressed Concrete Qcp Checklist - Dot State Fl

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to use or fill out the Prestressed Concrete QCP Checklist - Dot State Fl online

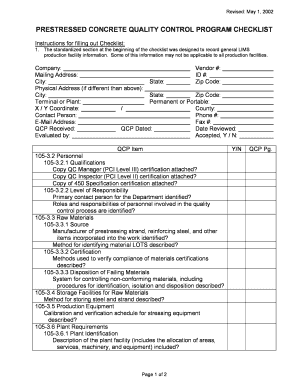

Filling out the Prestressed Concrete Quality Control Program (QCP) Checklist accurately is crucial for ensuring compliance with quality standards in construction. This guide provides step-by-step instructions to assist users in completing the form effectively online.

Follow the steps to complete the Prestressed Concrete QCP Checklist.

- Click 'Get Form' button to obtain the form and open it in the editor.

- Begin by entering the company name, vendor number, mailing address, and corresponding city, state, and zip code for the production facility. If the physical address differs, provide that information as well.

- Specify whether the facility is a terminal or plant and indicate whether it is permanent or portable. Fill in the X/Y coordinate details and the county where the facility is located.

- List the contact person’s name, phone number, email address, and fax number for further communication.

- Record the date the QCP was received, dated, and reviewed. Make sure to include the name of the evaluator and whether the QCP was accepted (yes or no).

- For section 105-3.2, provide details regarding personnel qualifications by confirming attachments related to the certifications of the Quality Control Manager and Inspector. Also, identify the primary contact person and their responsibilities.

- In section 105-3.3, describe the source of raw materials, including the manufacturer of prestressing strand and reinforcing steel, along with methods for identifying material lots and verifying compliance of material certifications.

- Ensure you detail the methods for controlling non-conforming materials and the storage facility methods for steel and strand in sections 105-3.4 and 105-3.5.

- Provide a calibration and verification schedule for the production equipment and describe plant identification and facilities in section 105-3.6.

- Document the process control system, including the frequency and methods of inspections, and specify how finished products are handled and stored.

- Include additional requirements such as quality control stamps, product certifications, management’s statement of compliance, and documentation procedures mentioned in section 105-3.7.

- In the final sections, describe storage method for the final product and procedures for inspecting concrete repairs before concluding the checklist.

- Once completed, review all entries for accuracy. Users can then save changes, download the completed form, print it, or share it as necessary.

Take time to complete the Prestressed Concrete QCP Checklist online to ensure compliance and quality in your construction projects.

Related links form

0:00 1:06 How To Create A Charter Email Account - YouTube YouTube Start of suggested clip End of suggested clip And it's grey box all your email addresses will pop. Up. Click add new email here type in an email aMoreAnd it's grey box all your email addresses will pop. Up. Click add new email here type in an email a password click save it'll come up in the list right here and that's all there is to it.

Industry-leading security and compliance

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.