Loading

Get Battery Manufacturing Process Flow Chart 2020-2025

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Battery Manufacturing Process Flow Chart online

This guide is designed to assist you in accurately completing the Battery Manufacturing Process Flow Chart online. By following the steps outlined below, you will be able to effectively navigate the form's sections and ensure all necessary information is provided.

Follow the steps to complete the Battery Manufacturing Process Flow Chart online.

- Click ‘Get Form’ button to obtain the form and open it in the editor.

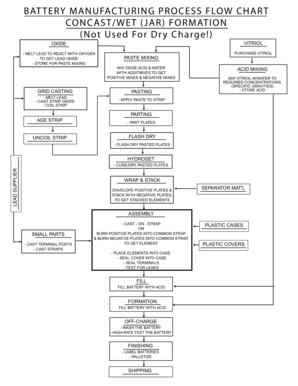

- Begin by reviewing the sections of the chart such as ‘Concast/Wet (Jar) Formation’ and ensure you understand each component's purpose.

- Proceed to the ‘Vitriol’ section where you will document the process of melting lead to react with oxygen and obtaining lead oxide. Ensure you note the storage requirements for paste mixing.

- In the ‘Paste Mixing’ field, enter your mixture details by combining oxide with acid and water, along with any additives for positive and negative mixes.

- For the ‘Grid Casting’ section, describe how you will melt lead and cast strip grids, ensuring that this process is clearly outlined.

- In ‘Pasting,’ accurately document the application of paste to the strip as part of the manufacturing steps.

- Make sure to include the details under the ‘Acid Mixing’ section, stating how vitriol is mixed with water and its required concentrations.

- Document the ‘Parting’ process by noting the aging and uncoiling of strips.

- For ‘Flash Dry,’ specify your method for flash drying pasted plates to ensure they are ready for the next stage.

- In the ‘Hydroset’ section, detail how you will cure or dry pasted plates.

- For ‘Wrap & Stack,’ explain how you will envelope positive plates and stack them with negative plates.

- Ensure to input information about small parts casting in the ‘Assembly’ section, detailing the casting of terminal posts and straps.

- In the ‘Fill’ section, indicate the process of filling the battery with acid.

- Document the ‘Formation’ steps along with any specifics required in the off-charge testing.

- Conclude by filling out the ‘Finishing’ section, providing details on labeling and palletizing the batteries.

- Finally, review all entries for accuracy, then save changes, download, print, or share as necessary.

Complete your documents online for efficient battery manufacturing management.

The components of battery production include electrodes, electrolyte, separators, and the outer casing. Each part plays a specific role in ensuring the battery operates efficiently and safely. To fully understand how these elements integrate, you can refer to a Battery Manufacturing Process Flow Chart, which clearly shows the relationship between each component.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.