Loading

Get Performance Qualification Test Record - American Welding Society - Aws

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Performance Qualification Test Record - American Welding Society - Aws online

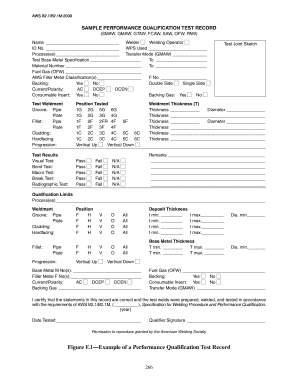

The Performance Qualification Test Record is a crucial document for verifying welding skills and qualifications as set forth by the American Welding Society. This guide provides clear, step-by-step instructions to assist users in accurately completing the form online.

Follow the steps to successfully complete the Performance Qualification Test Record

- Press the ‘Get Form’ button to obtain the Performance Qualification Test Record. Once you have the form, open it in your preferred editor.

- Begin by filling in the welder's name and welding operator ID number. Ensure these details are accurate to reflect the individual taking the test.

- Enter the Welding Procedure Specification (WPS) used for the qualification test. This section is essential for ensuring that the correct standards are adhered to.

- In the process(es) section, specify the welding processes employed, such as SMAW, GMAW, GTAW, FCAW, SAW, OFW, or PAW. Ensure this aligns with the WPS you referenced.

- Complete the test base metal specification by entering the relevant material information. This includes the material number and any additional specifications necessary for the qualification.

- Indicate whether backing is used in the welding process by selecting yes or no. If applicable, specify whether it is single side or double side backing.

- For the current/polarity section, select the type of electrical current being used — AC, DCEP, or DCEN.

- Fill in the test weldment details, including groove type (e.g., pipe, plate, fillet) and other relevant specifications about the weldment.

- Document the position tested, selecting the relevant position from the list provided (e.g., 1G, 2G, etc.). Ensure that you check all applicable positions if multiple positions are tested.

- In the test results section, record the outcomes of various tests, including visual, bend, macro, break, and radiographic tests, marking pass or fail as appropriate.

- Use the test joint sketch area to illustrate the weld joint configuration, including relevant dimensions such as thickness and diameter.

- In the remarks section, provide any additional notes or observations pertinent to the qualification test.

- Specify qualification limits including processes, positions, deposit thickness, and base metal thickness. Take care to complete these sections meticulously to ensure compliance with AWS standards.

- Finally, certify that the information is accurate, sign, and date the form to complete the qualification record.

- Once all fields are filled out and verified, you can save changes, download, print, or share the completed test record as needed.

Complete your documents online today to ensure compliance and validation of welding qualifications.

The AWS D1. 1 Structural Welding Code (Steel) welder qualification plate tests consists of a groove weld with a 45-degree included angle. The plates are prepared to a knife's edge and a ¼ in [6 mm] backing strip is used.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.