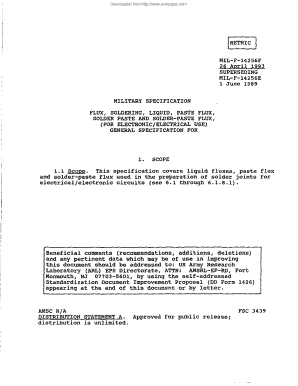

Get Mil-f-14256 F Flux Soldering Liquid Paste Flux Solder - Everyspec

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Mil-F-14256 F Flux Soldering Liquid Paste Flux Solder - EverySpec online

This guide provides clear and concise instructions on how to successfully complete the Mil-F-14256 F Flux Soldering Liquid Paste Flux Solder form online. By following these steps, users will navigate through the form efficiently, ensuring all necessary information is accurately submitted.

Follow the steps to fill out the form online seamlessly.

- Use the ‘Get Form’ button to access the form, which will open it in your preferred editor.

- Begin by filling out the identification section of the form, which typically includes your name, organization, and date of the application. Ensure that you provide accurate and up-to-date information.

- Proceed to the specifications section where you need to select the appropriate type of flux you are applying for. These may include options like Type R, RMA, or WSF-1. Ensure you read the descriptions carefully to select the correct one.

- In the requirements section, indicate the necessary materials and compliance details as specified in the document. Use a checklist to ensure all components match the required specifications.

- Complete the safety and health requirements section, confirming that you are aware of the proper handling and disposal guidelines any applicable hazardous materials.

- Review all filled fields to ensure accuracy and completeness. Correct any errors found to avoid processing delays.

- Once you have completed and validated the form, you may choose to save your changes, download a copy for your records, print the form, or share it as needed.

Start completing your Mil-F-14256 F Flux Soldering Liquid Paste Flux Solder form online today!

1:10 3:24 Using Flux | Soldering Basics - YouTube YouTube Start of suggested clip End of suggested clip Together flux is used to remove the oxide layer from the copper. And from the solder. The way itMoreTogether flux is used to remove the oxide layer from the copper. And from the solder. The way it does this is kind of interesting. It doesn't do much at low temperatures.

Industry-leading security and compliance

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.