Loading

Get Piping-welding-log-quality-control-and-inspection-form

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Piping-Welding-Log-Quality-Control-and-Inspection-Form online

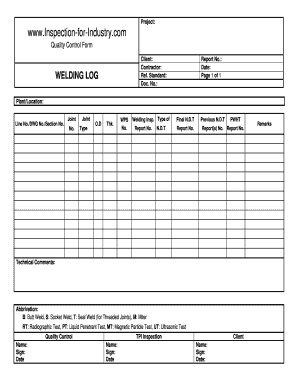

Filling out the Piping-Welding-Log-Quality-Control-and-Inspection-Form online can streamline your quality control and inspection process in welding projects. This guide will walk you through each section of the form, providing clear and concise instructions for completing it accurately.

Follow the steps to complete the form effectively.

- Click ‘Get Form’ button to obtain the form and open it in the editor.

- Enter the client name and contractor details in the appropriate fields. These details help identify who is responsible for the project.

- Fill in the reference standard and document number. This information ensures the form complies with relevant regulatory standards.

- In the welding log section, include the report number, date, and location of the project in the designated fields. Accurate documentation is crucial for tracking progress.

- Enter the line number, drawing number, and section number related to the welding work. This section organizes the log by specific project components.

- Document the joint number, joint type, outside diameter (O.D.), and thickness in the appropriate fields for detailed records of each welding joint.

- Further, provide the welding procedure specification (WPS) number and the type of report for welding inspection. This ensures that inspections are aligned with established procedures.

- Include the non-destructive testing (N.D.T) report numbers and technical comments, providing insight into the quality and integrity of the welding work performed.

- Fill in the fields for post-weld heat treatment (PWHT) reports to document any thermal processing done after welding.

- Complete the quality control section with your name, signature, and date. This certifies the accuracy of the information provided.

- Enter the name, signature, and date for third-party inspection (TPI) and client. This step confirms that all parties reviewed and approved the work.

- Lastly, add any remarks necessary that may provide additional context or information regarding the welding activities.

- Once everything is filled out, save changes, and consider downloading, printing, or sharing the completed form as required.

Start completing your Piping-Welding-Log-Quality-Control-and-Inspection-Form online today for efficient project management.

In welding, QA/QC plays a vital role in ensuring sound and reliable welds are produced and in minimizing rework. Quality Assurance (QA) is a set of defined processes for systematic monitoring and evaluation to assure product quality.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.