Loading

Get Sample Form For Welding Procedure Qualification Record (pqr)

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the SAMPLE FORM FOR WELDING PROCEDURE QUALIFICATION RECORD (PQR) online

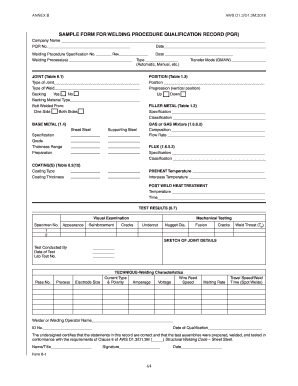

Filling out the Sample Form for Welding Procedure Qualification Record (PQR) online is a critical step in documenting welding procedures. This guide will provide you with clear, step-by-step instructions to ensure a smooth and accurate completion of the form.

Follow the steps to accurately complete the form.

- Click ‘Get Form’ button to obtain the form and open it in your preferred online editor.

- Enter your company name in the designated field at the top of the form. Ensure the name is spelled correctly to avoid any discrepancies.

- Fill in the PQR number, which should be unique for each record to maintain consistency and traceability.

- Insert the date of completion in the appropriate section to document when the form is filled.

- Provide the Welding Procedure Specification number and revision date. This identifies the specific welding procedures being qualified.

- Indicate the transfer mode and list the welding processes used. You should specify whether the procedure is automatic, manual, or other relevant types.

- In the JOIN section, describe the type of joint and its position based on the classifications provided. Refer to Table 6.1 for guidance.

- Fill in the type of weld and its progression. Specify whether backing is used, along with the backing material type.

- Complete the section for filler metal by selecting whether it is applied on one side or both sides, along with the specification and classification information.

- Provide details for the base metal; ensure to mention the grade and thickness range to be used.

- Outline the gas or gas mixture specifications including composition and flow rate for accurate documentation.

- If applicable, complete the section on flux specifications and classifications.

- Document any coatings used, including the type and thickness, for comprehensive records.

- Fill in the preheat and interpass temperatures, along with any post weld heat treatment details such as temperature and time.

- Record test results including visual examination details and mechanical testing results, ensuring accuracy in any measurements.

- Provide a sketch of joint details at the specified section and include who conducted the test along with the date.

- Document the pass number, process, and electrode size to complete the testing section.

- Fill in the technique-welding characteristics, including current type, wire feed & polarity, and other relevant parameters.

- Finally, ensure that the welder or welding operator's name and ID number are filled out along with the date of qualification.

- After completing all sections, review the form for accuracy before saving changes, downloading, printing, or sharing as necessary.

Complete your Welding Procedure Qualification Record (PQR) online today to ensure compliance and accuracy.

A WPS and PQR are required documents in the fabrication process when a weld must comply with a certain standard. In simple terms, a WPS is a set of welding instructions and the PQR is a checklist to ensure those instructions were satisfactorily met. The PQR document is created first and is needed to create the WPS.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.