Loading

Get Qw-483 2010

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the QW-483 online

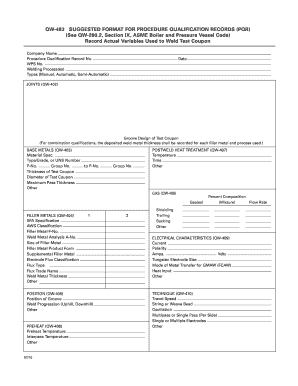

Filling out the QW-483 form online is an essential step in documenting procedure qualification records for welding processes. This guide will provide you with a clear, step-by-step approach to ensure you complete the form accurately and efficiently.

Follow the steps to successfully complete the QW-483 form:

- Press the ‘Get Form’ button to acquire the QW-483 form and open it in your browser for editing.

- Begin by entering the company name at the top of the form, followed by the procedure qualification record number and the WPS number. Ensure you have these identifiers correctly filled out as they are vital for record-keeping.

- Input the welding process used, specifying whether it was manual, automatic, or semi-automatic. Include the date of the qualification record to maintain accurate timelines.

- Move on to the 'Joints' section, where you will need to describe the groove design of the test coupon. If applicable, note the deposited weld metal thickness for each filler metal and process used.

- In the 'Base Metals' section, provide the material specification, type or grade, or UNS number. Include details about the P-No., group number, the thickness of the test coupon, diameter, and maximum pass thickness.

- Complete the post-weld heat treatment section by recording the temperature, time, and any other relevant details.

- Fill out the gas section by listing the gas or gases used in the welding process.

- In the 'Filler Metals' section, document the SFA specification, AWS classification, filler metal F-number, size, product form, and any other pertinent information.

- Provide details about the welding position, weld progression (uphill or downhill), and any other related information in the 'Position' section.

- Record your preheat temperatures and interpass temperatures in the preheat section, if applicable.

- Next, fill in the electrical characteristics, including current, polarity, amps, volts, tungsten electrode size, and details regarding heat input.

- Complete the technique section, documenting the travel speed, type of bead (string or weave), and whether you are using single or multiple electrodes.

- Proceed to the back of the form to input results from tests conducted, including tensile tests, guided-bend tests, toughness tests, and fillet-weld tests. Ensure you provide detailed results for each test.

- Finally, certify the document by inserting the manufacturer or contractor's name, date, and the certified person's signature.

- Once all sections are completed, you can save your changes, download the form, print it, or share it as needed.

Complete your documents online today and ensure your welding qualifications are properly recorded.

Get form

Experience a faster way to fill out and sign forms on the web. Access the most extensive library of templates available.

Related links form

The process qualification record, often abbreviated as PQR, is a detailed account of the welding parameters and test results that demonstrate a welding procedure's effectiveness. This record is vital for proving that welding techniques conform to industry standards and the requirements set by QW-483. Maintaining a clear PQR enhances traceability and accountability in the welding industry.

Get This Form Now!

Use professional pre-built templates to fill in and sign documents online faster. Get access to thousands of forms.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.