Loading

Get Rigging Inspection Log

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Rigging Inspection Log online

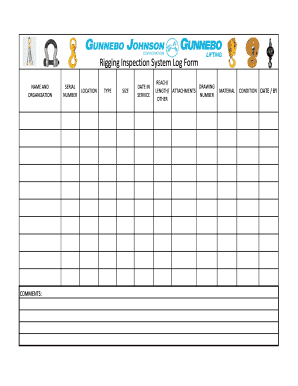

Filling out the Rigging Inspection Log online helps ensure that all necessary data is captured in a systematic and organized manner. This guide will walk you through each section of the log to help you complete it accurately and efficiently.

Follow the steps to fill out the Rigging Inspection Log seamlessly.

- Click ‘Get Form’ button to access the form and open it in the appropriate online editor.

- Begin by entering your name and organization in the designated fields. This provides essential identification information.

- Fill in the serial number associated with the rigging equipment. This number is crucial for tracking and verification purposes.

- Input the location where the equipment is being inspected. Precise location details help in maintaining accurate records.

- Select the type of rigging equipment from the options provided. This categorization aids in understanding the equipment's function.

- Specify the size of the equipment. Providing size dimensions is important for safety and compliance.

- Enter the date the equipment was put into service. This information helps assess how long the equipment has been in use.

- Document the reach or drawing length, including any attachments. This section ensures that all relevant measurements are recorded.

- Describe the material used for the rigging equipment. Knowing the material is vital for assessing its strength and durability.

- Provide notes on the condition of the equipment and the date of assessment, along with the person who performed the inspection in the comments section.

- Once you have completed all sections, you can save your changes, download a copy for your records, print the form, or share it with relevant parties as necessary.

Complete your Rigging Inspection Log online today to enhance your equipment management process.

To be OSHA and ASME compliant always make sure your rigging hardware is not bent or stretched, your shackles have the proper pin, and that your hooks have properly functioning safety latches. TSRE rigging inspectors also often see rigging hardware that has been improperly “repaired” by welding.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.