Loading

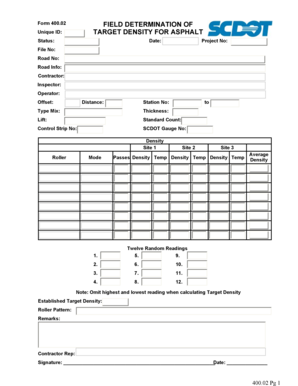

Get Form 40002 Field Determination Of Target Density For Asphalt Concrete Materials Form 40002 Field

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Form 40002 Field Determination Of Target Density For Asphalt Concrete Materials Form online

Filling out the Form 40002 Field Determination Of Target Density For Asphalt Concrete Materials is an essential part of ensuring accurate density measurements for asphalt concrete. This guide provides clear instructions on completing the form online, ensuring all necessary information is accurately reported.

Follow the steps to effectively complete the form online.

- Click ‘Get Form’ button to access the form and open it in the editor.

- Select the date on which the form is being filled out.

- Verify the file number associated with the project.

- Enter the project number to ensure proper identification.

- Input the road number relevant to the project.

- Fill in any additional information related to the road.

- Select the name of the prime contractor responsible for the project.

- Select the name of the inspector overseeing the work.

- Select the name of the operator conducting the density tests.

- Input the offset value pertinent to the measurements.

- Fill in the distance for the test locations.

- Fill in the station numbers that correspond to the testing sites.

- Specify the type of asphalt mix that is being utilized.

- Enter the thickness of the asphalt layer being tested.

- Indicate the lift number for the asphalt layer.

- Provide the standard count for the test.

- Fill in the control strip number relevant to the density testing.

- Enter the SCDOT gauge number to link the measurement tool used.

- Select the type of roller used during the operation.

- Choose the mode under which the roller operates.

- Input the number of passes made by the roller over the test sections.

- Fill in the density measured at Site 1.

- Record the temperature observed at Site 1.

- Input the density measured at Site 2.

- Record the temperature observed at Site 2.

- Fill in the density measured at Site 3.

- Record the temperature observed at Site 3.

- Calculate the average density by adding densities from the three sites and dividing by three.

- Fill in the twelve random readings taken during the testing.

- Verify the established target density by omitting the highest and lowest readings, then averaging the remaining ten readings.

- Fill in the roller pattern used during the compaction process.

- Add any remarks that are pertinent to the recording.

- Select the contractor’s representative and obtain their signature, along with the date.

Complete your forms online with confidence and ensure accurate density reporting.

The normal target in-place density on a “dense” hot-mix asphalt pavement is 92 to 93 percent of Gmm (or 7 to 8 percent air voids). If a pavement has low density (usually defined as less than 92 percent of Gmm), the air voids are interconnected and premature pavement distresses can result.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.