Loading

Get Welding Inspection Report

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Welding Inspection Report online

The Welding Inspection Report is an essential document that ensures compliance with quality standards in welding projects. This guide provides clear, step-by-step instructions on how to fill out the report online, making the process accessible for all users.

Follow the steps to complete the Welding Inspection Report online.

- Click the ‘Get Form’ button to obtain the Welding Inspection Report and open it in the editor.

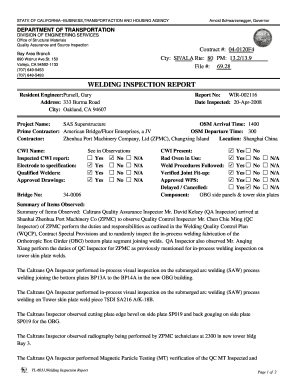

- Fill in the contract number and the county information as required in the designated fields. Ensure that you check the correct route and project details.

- Enter the resident engineer's name and address accurately. This information is crucial for identifying the responsible party for the inspection.

- Document the report number and date inspected. These details are vital for tracking the inspection history.

- Provide the project name and the names of the prime contractor and subcontractor. Ensure correct spelling and organization names are used.

- In the observations section, indicate whether various quality control measures were present, such as the presence of the Certified Welding Inspector and whether specific weld procedures were followed.

- Summarize the items observed during the inspection, detailing the processes witnessed and any relevant findings, ensuring to reference any test reports.

- Complete the summary of conversations if applicable and add any necessary comments that may provide further clarification regarding the inspection.

- After all fields are complete, review the information for accuracy. Once confirmed, save your changes, and you may choose to download, print, or share the form as needed.

Begin filling out your Welding Inspection Report online today to ensure compliance and efficiency in your projects.

Weld inspections are conducted for several reasons, the most common of which is to determine whether the weld is of suitable quality for its intended application. To evaluate the quality of a weld, you must first have criteria to which you can compare the weld's characteristics.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.