Loading

Get Form Qb-483 Suggested Format For A Brazing ... - Asme

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

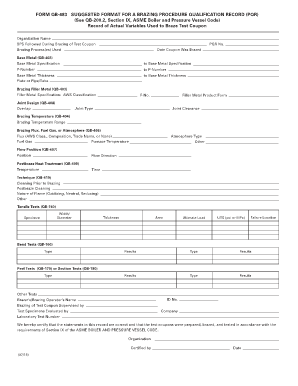

How to use or fill out the FORM QB-483 SUGGESTED FORMAT FOR A BRAZING PROCEDURE QUALIFICATION RECORD (PQR) online

Filling out the FORM QB-483 is a crucial step in documenting the brazing process in accordance with ASME standards. This guide provides a clear and comprehensive approach to ensure that all necessary information is completed accurately and thoroughly in the online format.

Follow the steps to effectively complete the brazing procedure qualification record.

- Press the ‘Get Form’ button to access the FORM QB-483 and open it in your preferred online document editor.

- Fill in the 'Organization Name' field with the legal name of the organization responsible for the brazing work. This ensures proper identification.

- Enter the 'PQR No.' in the specified area to uniquely identify this qualification record and maintain an organized documentation system.

- In the 'Brazing Process(es) Used' section, list all brazing methods employed. Ensure that you are specific to facilitate clarity and adherence to standards.

- Document the 'Date Coupon Was Brazed' to provide a record of when the process took place.

- For the 'Base Metal', indicate the specifications and type. This includes entering the 'Base Metal Specification' and relevant 'P-Number' and 'Base Metal Thickness.'

- Complete the 'Brazing Filler Metal' section, including 'Filler Metal Specification', 'F-Numbers', and 'Product Form', ensuring compliance with AWS classifications.

- In the 'Joint Design' area, define parameters such as 'Overlap', 'Joint Type', and 'Joint Clearance' to reflect the intended design.

- Specify the 'Brazing Temperature Range' to ensure correct application for the brazing process.

- Fill out the 'Brazing Flux, Fuel Gas, or Atmosphere' section, identifying the materials and conditions used during brazing.

- Complete the 'Flow Position' section by indicating the position and the flow direction during the brazing process.

- Document any 'Postbraze Heat Treatment' details such as temperature and treatment time to validate the quality of the brazing.

- Detail the 'Technique' used, which includes pre-cleaning and post-braze cleaning processes, as well as the nature of the flame implemented.

- Provide results from any required tensile and bend tests, including critical details such as specimen thickness and ultimate load.

- List any additional tests performed, including 'Peel Tests' or 'Section Tests', with their specific outcomes.

- Complete the certification section, providing the names of the individuals supervising the brazing, evaluating the test specimens, and certifying the form.

- After completing all fields, review your entries for accuracy and clarity. Save your changes, download the completed form, print it for records, or share it with stakeholders as needed.

Begin filling out your FORM QB-483 online to ensure compliance and streamline the documentation process.

ASME Section IX Code is set of rules, guidelines, and requirements for Welding, Brazing, and Fusing Qualifications. It is a reference code that helps for BPVC Construction Codes for Qualifications of Welder or Welding Operator, Brazer or Brazing Operator, and Fuser or Fusing Operator.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.