Loading

Get Blank Wps Form

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Blank Wps Form online

Filling out the Blank Wps Form can seem daunting, but with the right guidance, it can be a straightforward process. This guide will walk you through each section of the form, ensuring that you provide all necessary information accurately and effectively.

Follow the steps to complete the Blank Wps Form online.

- Press the ‘Get Form’ button to access the form and open it in your online document manager.

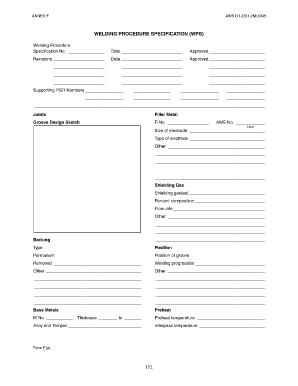

- Begin by entering the Welding Procedure Specification Number in the designated field, which helps to uniquely identify the specific welding procedure.

- Fill in the date of completion in the appropriate space and ensure that your entries are accurate.

- Identify the approval status of each section by entering the name or title of the person who approved the document, along with the date and any revisions made.

- Proceed to enter supporting PQR (Procedure Qualification Records) Numbers as needed, ensuring all relevant documentation is referenced.

- Detail the joints and filler metal specifics, including the F-Number, AWS Number, class, and size/type of electrode required for the procedure.

- Specify the shielding gas or gases involved, including their percent composition and flow rate, to ensure proper weld quality.

- Complete the sections regarding welding position and progression, as well as any backing requirements, ensuring each detail is comprehensive and clear.

- Include information about the base metals such as material thickness, temperature requirements, and alloy information to ensure compliance with standards.

- List the cleaning processes required, including initial, interpass, and post-weld treatments to maintain welding integrity.

- Document any post-weld heat treatment details, including temperatures and treatments applied to the finished weld.

- Lastly, review all sections thoroughly for accuracy before saving, downloading, or printing the completed form for your records.

Start filling out the Blank Wps Form online today to ensure a smooth and effective welding procedure specification process.

Related links form

With that said, who truly is the one to determine the range of approval of a WPS? Most, if not all, codes and specification require the approval by the responsible engineer, welding engineer, expert, supervisor, or welding coordinator (definition depending on the applicable code / specification).

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.