Loading

Get 6g Pipe Welding Code Procedure Papers

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the 6g Pipe Welding Code Procedure Papers online

Filling out the 6g Pipe Welding Code Procedure Papers is essential for ensuring compliance with industry standards in pipe welding. This guide provides clear instructions for users to complete the form accurately and efficiently.

Follow the steps to successfully complete your form.

- Press the ‘Get Form’ button to access the document and open it in your online editing tool.

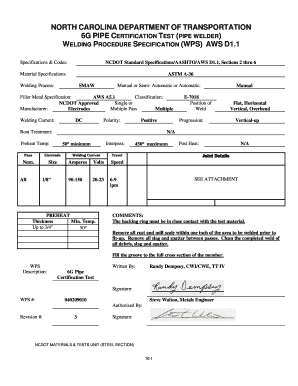

- Begin by entering the specifications of your welding procedure in the designated fields. You will need to include the applicable standards from the NCDOT and AASHTO/AWS D1.1 codes.

- Fill out the material specifications section by entering the correct material type, such as ASTM A-36.

- Specify the welding process you will use. Choose from the options provided, which may include manual, semi-automatic, or automatic methods, focusing on SMAW.

- Complete the filler metal information by selecting the appropriate classifications, such as AWS A5.1, and include the manufacturer’s name if required.

- Insert details regarding welding current, including polarity and amperes. Make sure to list all relevant parameters such as voltage and travel speed.

- Document the preheat temperature and interpass temperature requirements necessary for the welding procedure to ensure quality and safety.

- Provide joint details including any drawings or attachments that illustrate the joint structure and specifications. Ensure that all critical information is clear and accurately represents your welding approach.

- Enter the names and titles of the individuals responsible for the preparation and authorization of the welding procedure specification. Include the revision number of the document.

- After completing all sections of the form, review your entries for accuracy. Once satisfied, save your form, and choose to download, print, or share it as needed.

Get started on completing your 6g Pipe Welding Code Procedure Papers online today!

In the 6G pipe welding position, the pipe is at the slope or incline, approximately 45° from the horizontal (X) axis or from the vertical (Y) axis. The pipeline can be in a single or double offset. The pipe will be in a fixed position, so the welder needs to move around the pipe to perform the welding.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.