Loading

Get Ucn-1069 Upf Surface Preparation And Coating Inspection Record Ucn-1069 Upf Surface Preparation And

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

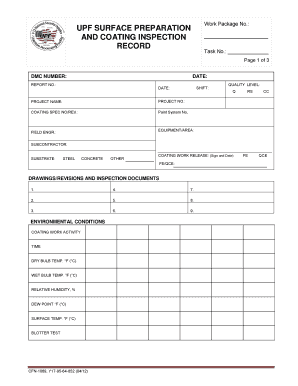

How to use or fill out the UCN-1069 UPF Surface Preparation And Coating Inspection Record online

This guide provides clear instructions on how to effectively complete the UCN-1069 UPF Surface Preparation And Coating Inspection Record online. By following these steps, you will ensure that all necessary information is accurately recorded for your coating inspection process.

Follow the steps to complete the UCN-1069 UPF Surface Preparation And Coating Inspection Record.

- Click ‘Get Form’ button to obtain the form and open it in the editor.

- Begin by filling out the 'Work Package No.' and 'Task No.' sections at the top of the form. This provides essential identifiers for your project.

- Next, enter the relevant information for 'DMC Number,' 'Date,' and 'Report No.' to document when and where the inspection is taking place.

- Fill in 'Project Name' and 'Project No.' to specify the scope of the work being inspected.

- Complete the 'Coating Spec No/Rev.' and 'Paint System No.' fields to indicate the specific materials and specifications being used.

- Provide details in the 'Shift' and 'Quality Level' sections, selecting the appropriate options that correspond to your work schedule and quality requirements.

- Identify the 'Equipment/Area' relevant to the activity being recorded, as well as details for 'Field Engineer' and 'Subcontractor', if applicable.

- Specify the 'Substrate' type by selecting either 'Steel', 'Concrete', or 'Other' as appropriate.

- In the 'Coating Work Release' section, ensure that the responsible party signs and dates the document.

- Record the environmental conditions during the coating work activity, including temperatures and humidity, in the designated fields.

- Proceed with detailing the 'Pre-Surface Preparation' steps which include 'Solvent Cleaning' and 'Masking/Protection' actions taken.

- Indicate the 'Surface Preparation Method' and provide details about the 'Abrasive Type/Size/Storage'.

- Fill out the 'Coating Materials & Mixing' section, recording batch numbers, mixing ratios, and product specifications.

- Detail the 'Coating Application' parameters including start time, finish time, and curing requirements.

- Verify the final inspection of the applied coating, noting any discrepancies in visual inspection and dry film thickness as required.

- Document calibration details for M&TE used, ensuring you list each piece of equipment with its corresponding serial number and calibration due date.

- Once all sections are completed, save your changes, and you may download, print, or share the form as necessary.

Complete the UCN-1069 UPF Surface Preparation And Coating Inspection Record online today to ensure streamlined documentation of your project.

After the "Final Action Dates" chart shows that your priority date is current, applicants will have one year to contact the NVC and pursue their green cards.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.