Loading

Get Questionnaire - Fm369

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Questionnaire - Fm369 online

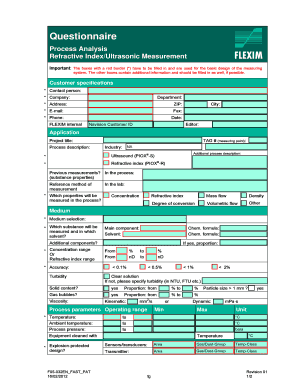

The Questionnaire - Fm369 is an essential document used for gathering specifications related to refractive index and ultrasonic measurement. This guide provides step-by-step instructions to help users fill out this form accurately and efficiently using an online platform.

Follow the steps to complete the Questionnaire - Fm369 online

- Click the ‘Get Form’ button to obtain the Questionnaire - Fm369 and open it in your online document editor.

- Begin by filling in the customer specifications section. Input the contact person's name, the company name, and the required information such as department, address, ZIP code, email, fax number, phone number, and date. Pay attention to the fields marked with a red border, as they are mandatory.

- Proceed to the internal FLEXIM section. Fill in the city and Navision customer ID if applicable.

- In the application section, provide the project title and a brief process description. Enter the measuring point TAG # and select the appropriate industry.

- Specify the ultrasound and refractive index measurements by indicating if there are previous measurements and describing the properties that will be measured in the process. Indicate whether the measurements are to be conducted in the lab or in the process, specifying the various properties such as concentration, refractive index, mass flow, etc.

- Continue by selecting the medium. Indicate the main component and solvent along with their chemical formulas, and provide any additional components if necessary. Fill in the concentration or refractive index range as required.

- Complete the accuracy and turbidity sections. Indicate if the solution will be clear or specify turbidity levels and proportions for solid content and gas bubbles if applicable.

- In the process parameters section, fill in details for operating range including temperature, ambient temperature, and process pressure.

- If applicable, provide information regarding explosion protection design, particle size, and specifications about the sensors/transducers.

- Fill in the pipe parameters for ultrasonic measurements, providing data about pipe material, outer diameter, wall thickness, lining material, and roughness.

- If involved with refractive index measurements, specify the type of connection and nominal diameter of the pipe.

- For the instrument design section, indicate the supply voltage, distance from transmitter to sensor/transducer, and details of the data logger and electrical outputs/inputs.

- Finally, review all the details for accuracy. Save any changes made to the form, and consider downloading, printing, or sharing it as needed.

Complete the Questionnaire - Fm369 online now to streamline your measurement specifications.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.