Get W/check Indust-form-08-afrik R3 - Wearcheck

How it works

-

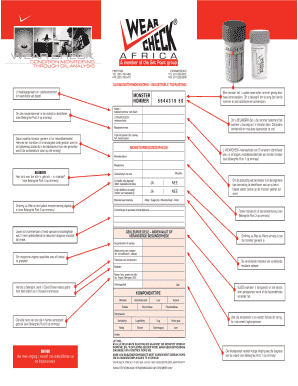

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to use or fill out the W/check Indust-Form-08-afrik R3 - WearCheck online

This guide provides users with step-by-step instructions to complete the W/check Indust-Form-08-afrik R3 - WearCheck online. By following this guide, you can ensure accurate and comprehensive submissions for your oil analysis.

Follow the steps to successfully complete the form online.

- Click ‘Get Form’ button to obtain the form and open it in the designated editor.

- Enter your company name and telephone number in the appropriate fields for identification purposes.

- Provide the machine number as required to accurately identify the equipment in the system.

- Fill in the sample number, ensuring its correspondence with the bottle number for tracking purposes.

- Specify the type of component (e.g., gearbox, hydraulic system, compressor) for precise identification.

- Record the date when the sample was taken for chronological order and monitoring.

- Indicate how long the oil has been used in months.

- Answer whether the oil has been drained by marking the appropriate checkbox.

- Specify if the oil filters have been replaced, if applicable, by checking 'Yes' or 'No'.

- Describe the sampling method used and any comments or special circumstances that may affect analysis.

- Fill in the total machine hours or service meter reading as requested.

- Provide details of the oil used, including name, type, grade, and ensure that it matches the component registered.

- Finally, review all entered information for accuracy before submitting. Users can save changes, download, print, or share the form as needed.

Complete the W/check Indust-Form-08-afrik R3 - WearCheck online to ensure prompt and accurate oil analysis.

A wear check is a process that evaluates the condition of machinery through oil analysis. Specifically, the W/check Indust-Form-08-afrik R3 - WearCheck identifies wear and contamination levels in the lubricants that power your equipment. This proactive analysis allows you to detect potential issues before they escalate, ensuring smooth operation. By understanding wear patterns, you can better maintain your equipment and reduce repair costs.

Industry-leading security and compliance

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.