Loading

Get Pqr Welding Form Filling Up

How it works

-

Open form follow the instructions

-

Easily sign the form with your finger

-

Send filled & signed form or save

How to fill out the Pqr Welding Form Filling Up online

The Pqr Welding Form is essential for documenting welding procedure qualifications. This guide provides clear, step-by-step instructions for filling out the form online, ensuring a smooth and accurate submission process.

Follow the steps to fill out the Pqr Welding Form with ease.

- Press the ‘Get Form’ button to acquire the Pqr Welding Form and open it in your preferred digital editor.

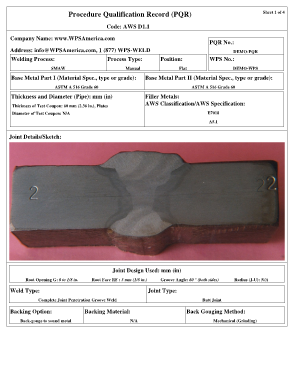

- Begin by entering the company name and Pqr number at the top of the form. Ensure that the company name is accurate and corresponds to the welding organization responsible for the record.

- Fill in the welding process and process type fields. For this form, the standard process is SMAW (Shielded Metal Arc Welding).

- Complete the Base Metal Part I section by indicating the material specifications, type, or grade. Refer to the relevant welding specifications to ensure correctness.

- In the Position field, denote the welding position; for example, you might enter 'Flat' if applicable.

- Proceed to Base Metal Part II and repeat the entry of material specifications, ensuring consistency with the first part.

- Fill in the Thickness and Diameter field (if applicable) and provide accurate measurements in both millimeters and inches.

- In the Filler Metals section, enter the AWS classification and specification number, confirming that they align with the materials being used.

- Document the details of the Joint Design Used, including root opening measurements, weld type, and joint type. Ensure all values are correct to prevent compliance issues.

- Proceed to the Electrical Characteristics section. Fill out details about the current type and polarity, as well as any other relevant welding parameters like gas flow rates if applicable.

- Complete the Welding Procedure details, specifying the number of passes, filler metal diameter, current settings, and travel speeds associated with the welding tasks.

- In the Heat Treatment section, note the preheat, interpass, and post-weld heat treatment temperatures to ensure compliance with AWS codes.

- In the Additional Notes field, provide any relevant specifics that relate to post-weld heat treatment guidelines.

- Ensure you fill in the fields for the Welding Engineer and the QA Manager, including their names, titles, and dates of authorization.

- Finally, review the entire form for accuracy. Once confirmed, you can save the changes, download, print, or share the form as needed.

Complete your Pqr Welding Form online today and ensure precise documentation of your welding procedures.

Making a PQR involves several key steps. First, you need to outline the welding processes and materials you will be working with. Then, perform the necessary tests to gather data that supports your Pqr Welding Form Filling Up. This comprehensive approach ensures your documentation reflects best practices.

Industry-leading security and compliance

US Legal Forms protects your data by complying with industry-specific security standards.

-

In businnes since 199725+ years providing professional legal documents.

-

Accredited businessGuarantees that a business meets BBB accreditation standards in the US and Canada.

-

Secured by BraintreeValidated Level 1 PCI DSS compliant payment gateway that accepts most major credit and debit card brands from across the globe.